Now we’re cooking with lasers

Columbia Engineers invent software-controlled robotic lasers that cook food with unparalleled precision, retaining more moisture, and creating an entirely new, customized way to cook a tasty meal.

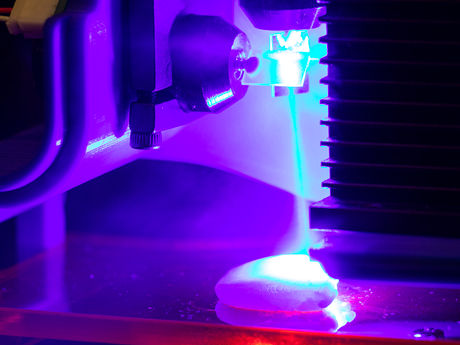

Chicken being cooked by a blue laser. Light is being directed by two software-controlled mirror galvanometers.

Jonathan Blutinger/Columbia Engineerin

Imagine having your own digital personal chef; ready to cook up whatever you want; able to tailor the shape, texture, and flavor just for you; and it’s all at the push of a button. Columbia engineers have been working on doing just that, using lasers for cooking and 3D printing technology for assembling foods.

Under the guidance of Mechanical Engineering Professor Hod Lipson, the “Digital Food” team of his Creative Machines Lab has been building a fully autonomous digital personal chef. Lipson’s group has been developing 3D-printed foods since 2007. Since then, food printing has progressed to multi-ingredient prints and has been explored by researchers and a few commercial companies.

“We noted that, while printers can produce ingredients to a millimeter-precision, there is no heating method with this same degree of resolution,” said Jonathan Blutinger, a PhD in Lipson’s lab who led the project. “Cooking is essential for nutrition, flavor, and texture development in many foods, and we wondered if we could develop a method with lasers to precisely control these attributes.”

In a new study published Sept. 1, 2021, by npj Science of Food, the team explored various modalities of cooking by exposing blue light (445 nm) and infrared light (980 nm and 10.6 μm) to chicken, which they used as a model food system. They printed chicken samples (3 mm thick by ~1in2 area) as a test bed and assessed a range of parameters including cooking depth, color development, moisture retention, and flavor differences between laser-cooked and stove-cooked meat. They discovered that laser-cooked meat shrinks 50% less, retains double the moisture content, and shows similar flavor development to conventionally cooked meat.

“In fact, our two blind taste-testers preferred laser-cooked meat to the conventionally cooked samples, which shows promise for this burgeoning technology,” Blutinger said.

While Lipson and Blutinger are excited about the possibilities of this new technology, whose hardware and software components are fairly low-tech, they note that there is not yet a sustainable ecosystem to support it. Lipson states that “what we still don’t have is what we call ‘Food CAD,’ sort of the Photoshop of food. We need a high level software that enables people who are not programmers or software developers to design the foods they want. And then we need a place where people can share digital recipes, like we share music.”

Still, says Blutinger, “Food is something that we all interact with and personalize on a daily basis--it seems only natural to infuse software into our cooking to make meal creation more customizable.”

Most read news

Other news from the department science

Get the food & beverage industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.