Gotcha! New technology speeds up bacterial testing in food

A promising technology that could potentially revolutionize the process of testing bacterial viability in food

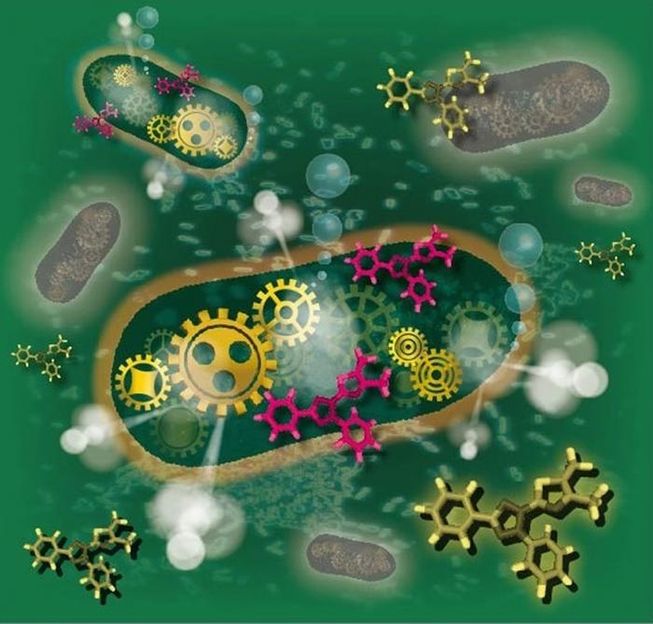

It is said that there is waste in haste, but researchers from Osaka Metropolitan University have proven that doing things rapidly does not necessarily mean working ineffectively. A research group led by Professor Hiroshi Shiigi at the Graduate School of Engineering, Osaka Metropolitan University has developed a technology that can rapidly and accurately determine the number of viable bacteria in food products electrochemically, using tetrazolium salt (MTT), a water-soluble molecule.

This technology accurately measures viable bacteria in food within 1 hour, as opposed to 2 days, regardless of bacterial species. Unlike existing technologies, this method does not require complicated operations or expensive equipment.

Hiroshi Shiigi, Osaka Metropolitan University

One of the most important assessment indicators for ensuring that food is free from contamination is the number of viable bacteria. However, conventional measurement methods take up to 2 days to yield results, and these results are only available after the food has been shipped from the factory—leading to potentially fatal consequences. Therefore, it is imperative to have a testing method that speeds up the process of identifying bacterial contamination before shipment.

The researchers have succeeded in drastically reducing the inspection time from 2 days to about 1 hour, regardless of the bacterial species. “With this method, we can quickly measure the number of viable bacteria, allowing us to confirm the safety of food products before they leave the factory and to prevent food poisoning,” Professor Shiigi explained. “This method does not require complicated operations or expensive equipment. Therefore, we will continue to optimize the measurement conditions and expect to see the development of a portable sensor in line with the development of research aimed at practical applications.”

Original publication

See the theme worlds for related content

Topic world Food safety

Food safety is at the heart of the food and beverage industry. It ensures that the food we eat every day is not only nutritious, but also free of harmful contaminants. From field to plate, the industry monitors and regulates every step of the process with strict quality controls, advanced testing methods and continuous research.

Topic world Food safety

Food safety is at the heart of the food and beverage industry. It ensures that the food we eat every day is not only nutritious, but also free of harmful contaminants. From field to plate, the industry monitors and regulates every step of the process with strict quality controls, advanced testing methods and continuous research.