Biodegradable materials - packaged in beer

Advertisement

Empa researchers have extracted nanocellulose from a beer brewery waste product and processed it into an aerogel. The high-quality material could be used in food packaging.

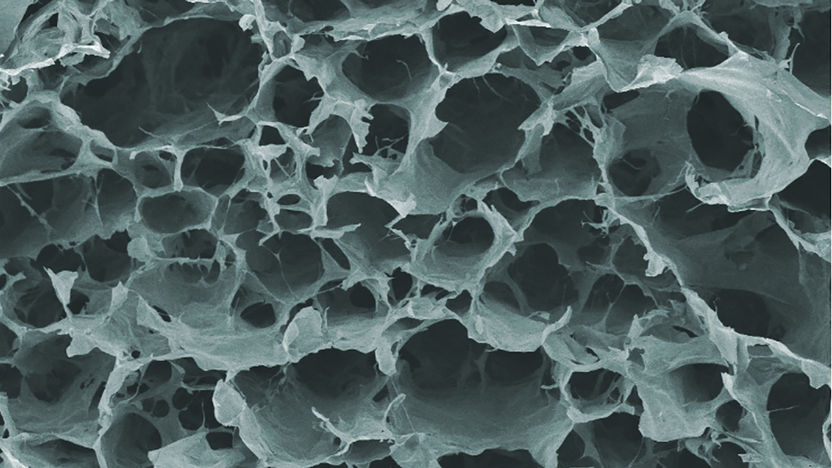

The typical airy structure of aerogel (electron microscopy, colored)

Empa

Process steps: From grain residue to aerogel.

Empa

In the beginning was the mash. The mixture of malt and water is stirred for several hours and gently heated. The resulting liquid is called wort and is turned into beer in further process steps. The spent malt - known as spent grains - has a far less glorious journey ahead of it. It usually ends up as animal feed or on the compost heap.

Researchers from Empa's "Cellulose and Wood Materials" laboratory, led by Gustav Nyström, have found that there is more to it. They have now developed a process to produce high-quality nanocellulose from brewery waste - a versatile biodegradable raw material that can be processed into packaging or fiber-reinforced plastics, for example. The researchers have now published their findings in the journal "ACS Sustainable Chemistry & Engineering".

Grain instead of wood

The first author of the study, Nadia Ahmadi Heidari, is a doctoral student at Isfahan Technical University. She came to Empa for a year as part of a Federal Excellence Scholarship. She was particularly interested in the production of biodegradable packaging materials from waste products - one of the focal points of the "Cellulose and Wood Materials" laboratory. "We are very interested in developing new sources of valuable raw materials such as cellulose fibers and lignin," says Gustav Nyström.

Micro- and nanofibrillated cellulose products are currently obtained from wood pulp. However, wood can be put to better use elsewhere. "Wood binds CO2 from the atmosphere very well, but only grows slowly," explains Nyström. "It is therefore much better suited for long-lasting applications, such as in construction or for the manufacture of furniture."

The much faster-growing annual plants can provide raw materials just as well, but have hardly been used for this purpose to date. "With our process, we can obtain high-quality materials from a very cheap and widely available waste product that is largely wasted today," adds Empa researcher Gilberto Siqueira, co-author of the paper. "This also benefits small companies that can get the most out of the raw materials they already use."

The spent grains that the researchers used for their experiment also came from one such small company, the Pentabier brewery in Dübendorf. They extracted the nanocellulose fibers from it and processed them into an aerogel by freeze-drying. This "airy" material contains a large number of pores, which gives it excellent thermal insulation properties. Aerogels can be made from different materials - silicate aerogels, which are used in construction, are particularly well known. Nanocellulose-based aerogels have additional advantages: they come from renewable sources and are biodegradable. The aim is to use them for packaging, particularly for temperature-sensitive foods such as meat.

Simple production

To explore the potential of nanocellulose from spent grains in more detail, the researchers varied the individual pre-treatment and production steps and tested their effects on the end product. For example, the quality of the nanocellulose fibers obtained is improved by bleaching and oxidizing the starting material. Different freezing processes can be used to control the size and orientation of the pores in the aerogel, which in turn influences its insulating and mechanical properties.

"We were keen to keep the whole process as simple as possible," says Siqueira. After all, if it is to be used in the real world, not only does the end product have to be convincing - it should also be as simple and cheap to produce as possible. This is another reason why the researchers are interested in obtaining raw materials from waste products. "Compared to residues from the agricultural industry, wood is an expensive source of cellulose, and it already has so many other applications," explains Siqueira. In further research projects, the scientists are therefore investigating other waste products from the food industry and forestry. And although Nadia Ahmadi Heidari has already returned to Isfahan Technical University, the Empa researchers are planning another publication together with the young researcher, in which they will describe the aerogels made from spent grains in more detail.

Note: This article has been translated using a computer system without human intervention. LUMITOS offers these automatic translations to present a wider range of current news. Since this article has been translated with automatic translation, it is possible that it contains errors in vocabulary, syntax or grammar. The original article in German can be found here.