Start-up brings quantum sensor to market maturity

SpinMagIC receives EXIST research transfer funding

Advertisement

Whether beer, coffee beans, yoghurt or lubricating oil: a device that fits easily on a hand can measure the shelf life of substances. The idea: to bring the technology to the food industry. As a spin-off, the spin-off from the University of Stuttgart receives funding from the EXIST research transfer program of the Federal Ministry of Economics and Climate Protection (BMWK).

Physicist Belal Alnajjar (left) and electrical engineer Anh Chu from the start-up SpinMagIC work in the laboratories at the University of Stuttgart.

Kathleen Spilok

"The quantum sensor is already within reach. Now we have to bring it to the market with plenty of horsepower," says Prof. Jens Anders. This is exactly what four young men are working on. With their spin-off SpinMagIC, they want to make durability measurements as simple as possible with the help of a quantum sensor. Two of them, Belal Alnajjar and Anh Chu, are doctoral students of Anders and are working in the laboratories at the University of Stuttgart, at the Institute for Smart Sensors (IIS). The other two - physics doctoral student Michele Segantini and Jakob Fitschen, who is responsible for financially managing the spin-off and making it profitable - work from Helmholtz Zentrum Berlin (HZB), supported by Prof. Klaus Lips, head of the "Spins in Energy Conversion and Quantum Informatics" department. Anders and Lips are very familiar with the measurement of electron spin resonances, or ESR for short. A method that measures particularly reactive molecules. They were awarded the HZB Prize for Technology Transfer in 2019.

Teamwork in Stuttgart and Berlin to develop portable quantum sensor

The BMWK funding was awarded on October 1, 2024. The four founders now have two years to make their spin-off a success. The doctoral students are supported by the Institute for Entrepreneurship (ENI), the technology transfer initiative TTI GmbH and the TRACES transfer center at the University of Stuttgart as well as the state initiative "NXTGN" (formerly Gründermotor). The three doctoral students from Stuttgart and Berlin have been working together on different projects for several years and know each other very well. Jakob Fitschen joined them six months ago. Teamwork is the be-all and end-all in the development of the highly complex portable quantum sensor.

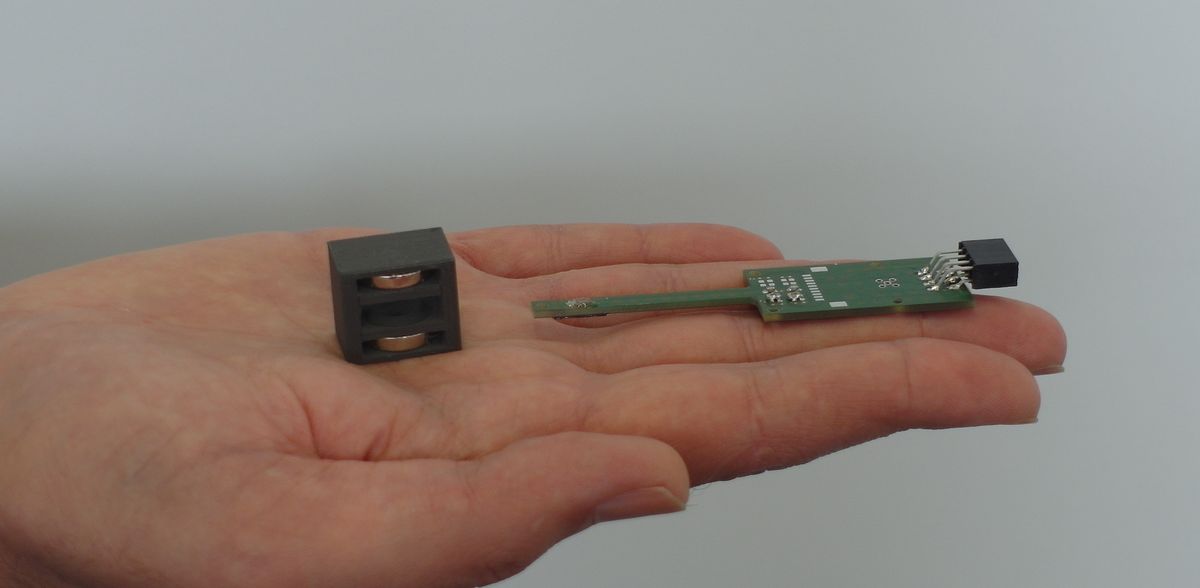

SpinMagIC focuses on quantum sensors that can be used to detect reactive molecules, free radicals. Any material that has unpaired electrons can be quantitatively measured with the sensor. Free radicals, for example, cause skin to age more quickly. They are also responsible for the decomposition of food. To make free radicals measurable, ESR has been around "for 80 years", notes Anders. Until now, their use was limited because the devices were too bulky, weighed at least a ton and cost several hundred thousand euros. Even available table-top devices weigh around 120 kilograms and are very expensive. A bottleneck problem that calls into question efficient processes or widespread use. This is now changing abruptly: miniaturization is the magic word. Because all the researchers need to measure shelf life is a small permanent magnet and a microchip with an integrated circuit.

Measuring the shelf life of liquids using free radicals

How does the measurement work? The microchip is actually no more than one square millimeter in size. It consists of high-frequency circuits that excite the unpaired electrons and record their quantum response. For the measurement process, the researchers switch on a micropump that transports the sample onto the chip or immerse the sensor directly in the liquid to be measured. A display shows the amount of free radicals in the sample. "This approach of 3D-printed structures made of lightweight filament provides a cost-effective way to realize high-performance resonance magnets," emphasizes physicist Alnajjar. Before the printing process, he carried out numerous simulations to find the best option. The magnet from the 3D printer now weighs around 40 grams. The inside of the magnet consists of rings. "The rings are chosen so that the magnetic field is very homogeneous," says Alnajjar. The low weight and high quality are key factors for these magnets.

The researchers are proud of the neologism SpinMagIC - three components of the measurement: Spin stands for the electrons, which have their own angular momentum, Mag for magnet, which enables the measurement, and IC for the integrated circuit. The division of tasks is clear: "We in Stuttgart are responsible for developing the core technology," emphasizes electrical engineer Chu. These are the permanent magnet and the circuit board that carries a tiny chip-integrated quantum sensor. Segantini, the physicist in Berlin, is looking at applications based on initial examples, such as measuring food shelf life. In particular, he has good connections in olive oil production. The plan is to have the end product ready for the market in two years and to acquire the first pilot customers who want to test it. "Extremely small and extremely inexpensive with a very high measurement accuracy," says Chu, emphasizing the high demands of the food industry and thus also its incentive.

Applications from the food industry to pharmaceuticals to environmental pollution

The process can also be used to determine the condition of batteries. Catalytic processes, which are often used in the chemical industry for the polymerization of molecules, could also follow. Processes from the pharmaceutical industry are also conceivable, as is contamination in the air or in water. "We have a fixed budget from the BMWK for the next two years," says Chu. Funding for the spin-off is therefore secured for this period. "But after that, we are open to venture capitalists or private investors."

The parts do not yet fit into a smartwatch. But the researchers have set their sights on incorporating the measurement equipment into an even smaller tool in the long term.

Note: This article has been translated using a computer system without human intervention. LUMITOS offers these automatic translations to present a wider range of current news. Since this article has been translated with automatic translation, it is possible that it contains errors in vocabulary, syntax or grammar. The original article in German can be found here.

Other news from the department science

These products might interest you

Most read news

More news from our other portals

Something is happening in the food & beverage industry ...

This is what true pioneering spirit looks like: Plenty of innovative start-ups are bringing fresh ideas, lifeblood and entrepreneurial spirit to change tomorrow's world for the better. Immerse yourself in the world of these young companies and take the opportunity to get in touch with the founders.