"Better Quality + Higher Yield = More Value"

With Slicers, Skinners, Food Robotics, Scanning Technology and Services, Weber Maschinenbau offers complete packages to improve efficiency and hygiene in the food industry.

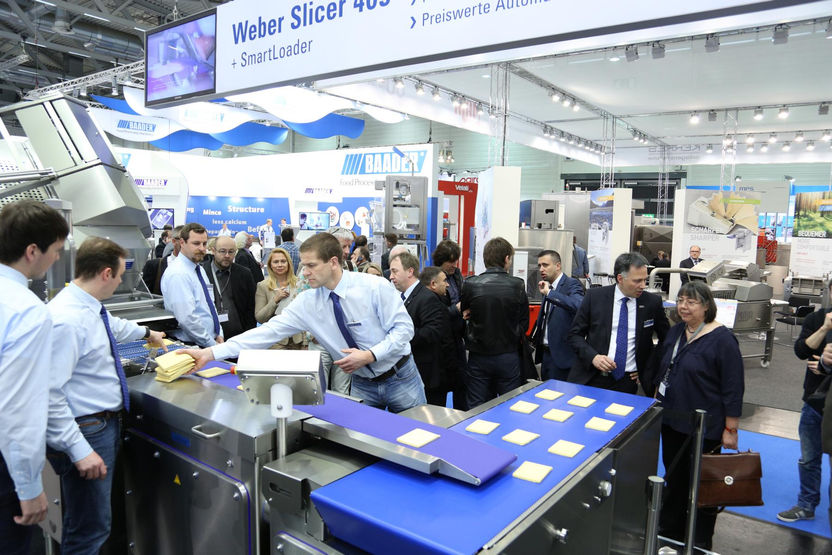

Weber Maschinenbau was showcasing new developments and updates to its existing product range at Anuga FoodTec 2015 in Cologne. Based on the motto "Better Quality + Higher Yield = Added Value", the Weber booth focused on innovative systems which can be used in food production to achieve maximum yield with minimum giveaway and excellent flexibility.

Anuga FoodTec 2015

Fotos: Weber Maschinenbau GmbH Breidenbach

"We want to use our stand at Anuga FoodTec to demonstrate to our customers in the international food industry the performance of our products for slicing, automation and scanning technology," explains Mathias Dülfer, Managing Director of Weber Maschinenbau. "With product and service componentswhich go beyond Weber Slicers and Skinners, we offer our customers the right solutions for their applications. These include the Weber After Sales Service with spare parts, blades, upgrades, Technical Service and used machines, as well as the Weber Campus for Service Training. With the new Weber Consult Service recently added to the portfolio, we now offer the additional opportunity to identify potential to increase efficiency on-site in production, develop strategies for improvement and implement these in conjunction with our customers," stresses Dülfer.

Established Weber machines used in conjunction with high-performance components to provide added value in the areas in which Weber customers operate were also be on show in Cologne: these include the 405 Slicer in conjunction with the SmartLoader recently developed by the Weber Group – a compact and flexible solution for loading cut foods into packaging.

Irrespective of the ambient light, the CPS 200 LED Scanner reliably scans products with dark surfaces, such as cutting quality natural products like Bündner air-dried meat or Serrano ham in order to improve yield at the same time as reducing giveaway. Weber Maschinenbau recently added Scanning Technology to its product range by taking a majority stake in Wente-Thiedig GmbH, one of Weber's major partners and supplier for camera and image processing systems and optical measurement technology. This in-sourcing of expert knowledge and skills in image processing should further increase benefits for Weber customers, for example by increasing system reliability in their applications. Scanning Technology is primarily used in the scanners and optic weighers on the Weber Slicers and the Weber Pick Robots.

The Weber Pick Robot (WPR) automatically detects products in all conventional portion shapes and sizes thanks to its integrated camera housing. It uses its grabber arm to remove the products from the transport conveyor, rotate them to the correct position and lay them accurately in the pack. This completely does away with human contact when loading the products, which considerably improves food safety. The WPR can be viewed with a compact buffer built into the picker housing at Anuga FoodTec for the first time. This is one example solution showing how maximum flexibility can be achieved for unmanned production even on a very small footprint.

Weber Durablade® circular and involute blades are made of stainless steel and are designed to be hygienic and durable. They cut virtually any lunch meat and ham types without a non-stick coating. Durablade® involute blades can also be fitted with Weber-patented multi-angles for particularly difficult, special applications. The expansion of the product range means Durablade® is now also available for non-Weber Slicers.

The SSM Sharpening Centre can be used to efficiently sharpen Weber Durablade® involute blades with a radius of 365 to 485 millimetres and circular blades with a diameter of up to 470 millimetres. The RFID scanner built into the Weber SSM can reproduce the individually customized sharpening programmes easily and consistently, as all Weber Durablade® blades are fitted with an RFID chip.

The Weber Skinner Product Department had its own booth at Anuga FoodTec 2015, right opposite the main Weber booth. Qualified experts will be there to answer all questions from interested visitors on anything relating to rind and membrane removal. The show featured machines from the current range for a wide variety of applications in industrial and medium-sized meat-processing businesses. For example, the Industry Skinner ASB 560, the sinew and membrane Skinner ASE Twin 533 and the unique belt Derinder ASW 560 will all be on show.