Contaminant-Free Meat and Sausages

Sesotec product inspection systems ready for Industry 4.0

At the IFFA 2016 in Frankfurt (hall 9.1, stand C58) Sesotec GmbH presents sophisticated metal and contaminant detectors and separators especially for the meat industry.

The VARICON+ and UNICON+ metal detection systems with the new INTUITY metal detector and the new design RAYCON D Product inspection system are presented as trade fair highlights. The spectrum of exhibited systems is completed by the LIQUISCAN metal separators for filler applications, systems that are well-proven in the meat industry.

The new Sesotec INTUITY metal detector uses multi-simultaneous-frequency technology for high-end metal detection. The also new design INTUITY CONTROL user interface is positioned ergonomically and provides even more ease of operation.

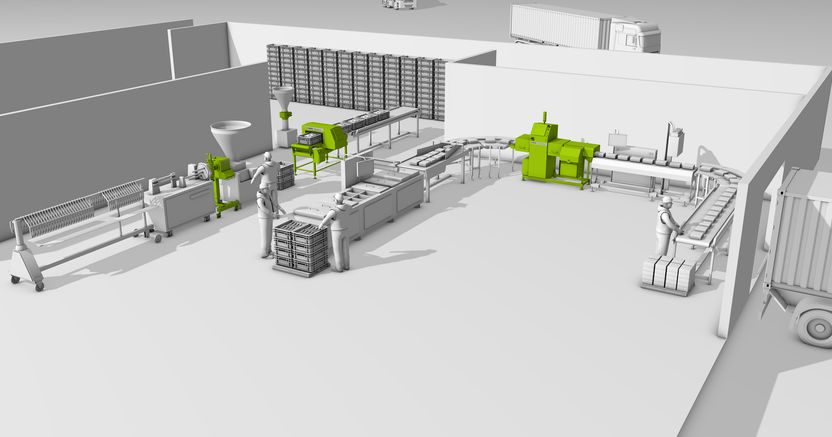

Foto: Sesotec

At the IFFA 2016 Sesotec presents the new RAYCON D X-ray scanner.

Foto: Sesotec

Ready for Industry 4.0 means that Sesotec product inspection systems feature the technical prerequisites (interfaces) both for processing "own" production data and for communicating with other machines in the plant.

Bildquelle: sesotec

Metal detection systems – high sensitivity and ease of operation

The metal detection systems are equipped with the new INTUITY metal detection coil. With multi-simultaneous-frequency technology INTUITY reaches a scanning sensitivity that is up to 50 percent higher than in other systems on the market. Since this coil operates with multiple frequencies in parallel, highest product purity is ensured also in demanding applications with a high product effect. With the new developed INTUITY CONTROL user interface the system also offers improved ease of operation.

With the VARICON+ and UNICON+ metal detection systems both packed products and meat that is transported in E1/E2 boxes (fresh or frozen) can be inspected for accidental metal contaminations. The systems even detect smallest metal particles in products and thus ensure that meat and sausage products are free from metallic contaminations.

X-ray technology a must in the meat industry

Product inspection systems operating with X-ray technology already are widely used in the meat industry. Sesotec's RAYCON D product inspection system primarily is used for the final inspection of packed products and allows high-precision inline detection of a wide variety of contaminants such as magnetic and non-magnetic metals, glass, ceramics, stones, raw bones, and some types of plastics. RAYCON D combines proven Sesotec X-ray technology with hygienic design and ease of operation.

With respect to hygienic design, the conveyor belt in the RAYCON D system can be replaced within two minutes by only one operator.

LIQUISCAN metal separators – compact and proven in thousands of applications

LIQUISCAN metal separators are especially designed for the inspection of sausage meat or similar pasty materials. With their compact design these separators can be directly installed at the outlet of a vacuum filler. When a metal contamination is detected the conveying process is stopped or a pneumatic reject valve automatically separates the contaminated sausage meat from the filling process into a collecting container. With different connections the system can be easily combined with all filler and clipper systems and various attachment units commonly used in the meat industry.

What all Sesotec systems have in common is a mechanical design that meets the special hygienic requirements of the food industry ("hygienic design"). Sesotec product inspection systems are "ready for Industry 4.0" and can be networked with other plant components, which increases the total efficiency, quality and flexibility of production.

Most read news

Topics

Organizations

Other news from the department business & finance

Get the food & beverage industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.

Most read news

More news from our other portals

See the theme worlds for related content

Topic World Foreign body detection

Detecting foreign objects in food and beverages is a critical step in ensuring the safety and quality of the products we consume every day. Whether through metal detectors, X-ray systems or optical detection methods, foreign object detection protects us from unwanted and potentially dangerous objects in our food.

Topic World Foreign body detection

Detecting foreign objects in food and beverages is a critical step in ensuring the safety and quality of the products we consume every day. Whether through metal detectors, X-ray systems or optical detection methods, foreign object detection protects us from unwanted and potentially dangerous objects in our food.

Topic world Quality assurance

In the food industry, quality assurance is about much more than safety. It's about ensuring consistent standards that meet consumers' taste, nutritional and aesthetic expectations. Using state-of-the-art analytical methods and strict protocols, Quality Assurance ensures that every product delivers on the brand's promise. From appearance and taste to texture and shelf life, Quality Assurance ensures consumers get exactly what they expect.

Topic world Quality assurance

In the food industry, quality assurance is about much more than safety. It's about ensuring consistent standards that meet consumers' taste, nutritional and aesthetic expectations. Using state-of-the-art analytical methods and strict protocols, Quality Assurance ensures that every product delivers on the brand's promise. From appearance and taste to texture and shelf life, Quality Assurance ensures consumers get exactly what they expect.