Smart coat for the „coldest beer in the world“

Smart Packaging is the current trend – providing not only pure visual effects but rather additional useful information to customers. By order of the the world’s second largest brewer SABMiller, Scientists of Fraunhofer EMFT have developed an interactive temperature sensor and display system, integrated into a portable ice box and showing whether the beer has the optimal drinking temperature.

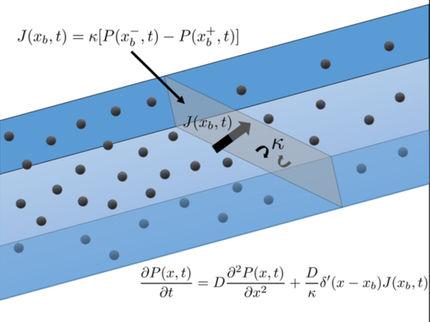

For many people, a cold beer is a must-have in summer – and for some people, it cannot be even cold enough: SABMiller recommends a drinking temperature of 4 C° to the customers of its Castle lite beer, distributed in South Africa. For the delight of their customers, some beverage shops in South Africa are currently participating in a world first promotional campaign by the brewer: A portable ice box which keeps the beer cold on the way. The special treat is an integrated temperature measuring system with a temperature sensor and a display, developed in collaboration with SABMiller and the scientists of the Fraunhofer research institution for microsystems and solid state technologies EMFT. The Munich experts have extensive experience in foil technology and flexible electronics – a knowledge that is currently in great demand: “Smart packaging”, meaning packaging with integrated electronics, is in line with market trends. However, this requires very flat and flexible devices that can be discreetly integrated in diverse materials and applied onto curved surfaces. For the temperature measuring system in the ice box, the Fraunhofer EMFT team of scientists placed the SMD circuitry and the coin cell for energy supply in a recess of the Styrofoam and combined it with a sensor stripe measuring the temperature inside the box. The display and the push button were placed on the outside of the box easily visible. All sensors and operating elements are very flat and were produced via printing technologies.

SABMiller-Ice box with integrated temperature measuring system.

Fraunhofer EMFT/Bernd Müller

Silicon and foil technology: A winning team

Smart packaging solutions that go beyond pure eye catcher functionality are more and more in demand: The packaging shall offer real additional value to the customer, e.g. by giving information on the properties and status of its contents. To realize even more complex functions for such smart packaging, the Fraunhofer EMFT scientists focus on the total integration of multifunctional systems into flexible substrates. Thereby, printing technologies meet classical technologies and processes, which can be developed further if required: For example “Dicing-by-thinning”, a thinning technology that was developed and patented at Fraunhofer EMFT, enables the production of silicon chips only 10 μm thin – this paves the way for a combination of silicon and foil technology, allowing the science team to use the advantages of both technologies: While silicon is unbeatable concerning size and performance, foil electronics with its flexibility allows for more scope in design.

Cost efficient production „off the reel”

For the SABMiller promotion action the Munich experts produced a limited edition temperature measuring systems. Reel to reel technology, which is well established at the Fraunhofer EMFT, is considered a promising approach to manufacture also high volumes of packaging electronics in a cost efficient way. Similarly to a newspaper printing machine, the diverse process steps for producing the flexible electronics are carried out while coiling a foil substrate (usually PET or polyamide foils) back and forth between two reels. This technology could prove itself to be a key factor for establishing “smart packaging” on the mass market.

Most read news

Other news from the department business & finance

These products might interest you

VEGABAR /VEGAPULS / VEGAPOINT by VEGA Grieshaber

Level and pressure sensors - CIP-cleanable up to 150 °C

Find out more about the hygienic, reliable and efficient sensors from VEGA

BUCHI NIR Solutions for the food industry by NIR-Online

Monitor processes in real time - even under harsh conditions

Measure moisture, protein, oil, ash, etc. simultaneously

Get the food & beverage industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.