Simply more transparency - two new X-ray systems for detecting foreign objects as well as product and packaging faults

HEUFT SYSTEMTECHNIK GMBH at FachPack 2016 in Nuremberg

HEUFT SYSTEMTECHNIK GMBH will be presenting two new X-ray systems with consistently further developed pulsed X-ray technology and simply more performance for detecting foreign objects as well as product and packaging faults at FachPack 2016 in Nuremberg, Germany. In addition innovative solutions for the detection of leaks in aerosol cans and the continuous traceability of primary packaging can be experienced on Stand 3 / 228.

HEUFT eXaminer II XB

HEUFT Systemtechnik GmbH

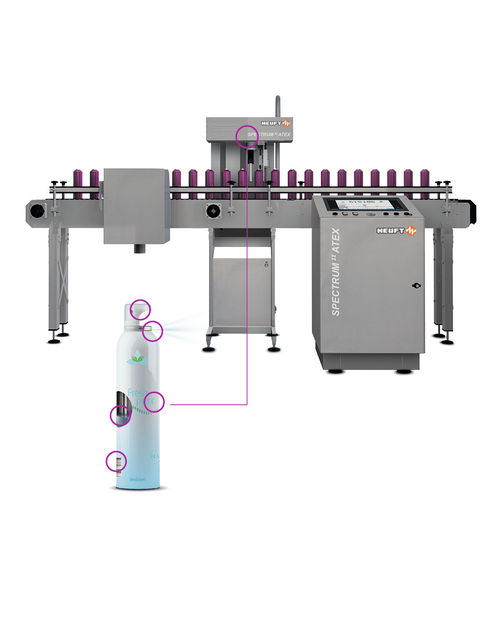

HEUFT Spectrum II ATEX

HEUFT Systemtechnik GmbH

Foreign objects in filled drinks packs, pouches, thermoform packaging or composite packages are a real safety risk. The HEUFT eXaminer II XB which the technology leader regarding quality inspection will be showcasing at the FachPack exhibition tracks them down in-line. The highly automated top-down inspector identifies minute contamination made of a wide variety of materials even in such opaque items of packaging using unique pulsed X-ray technology.

The audiovisual HEUFT NaVi user guidance makes error-free operation simply easy. The same also applies to the HEUFT eXaminer II XAC for the X-ray based detection of foreign objects in filled containers, jars and cans which can be experienced on the HEUFT stand in addition to innovations such as the HEUFT tracer D for the clear verification of 2D codes and the HEUFT SPECTRUM II ATEX for the detection of leaks in aerosol cans.

Quality, safety and efficiency: this is what matters when filling and packaging food, drinks and pharmaceuticals.

The modular solutions from HEUFT SYSTEMTECHNIK GMBH put these key factors into practice simply and effectively. They ensure, during maximum productivity, that only perfect products reach the market. Unique camera, X-ray and image processing technologies for a precise empty and full container inspection, trend-setting labelling technology and smart tools for container flow optimisation, production data acquisition and performance analysis safeguard product quality and line efficiency sustainably.

A consistent modular design principle with a cross-system control unit for the most varied technologies, procedures and modules generates, together with a high component equality, the correct automation solution for every application. Those who decide in favour of a user-friendly HEUFT system can depend on a high level of operational reliability. Competent support is always guaranteed with the long-term availability of spare parts and the 24/7 on call service. This concept keeps the globally operating company on a dynamic course of growth. In the meantime the number of employees has long since exceeded the 1,000 mark. Its own locations in 14 different countries and a comprehensive network of service bases on all five continents meet the huge demand for the HEUFT systems which are manufactured exclusively in Germany.The result: more safety, quality and efficiency during the filling and packaging of food, drinks and pharmaceuticals.

HEUFT knows how!

Other news from the department business & finance

Most read news

More news from our other portals

See the theme worlds for related content

Topic World Foreign body detection

Detecting foreign objects in food and beverages is a critical step in ensuring the safety and quality of the products we consume every day. Whether through metal detectors, X-ray systems or optical detection methods, foreign object detection protects us from unwanted and potentially dangerous objects in our food.

Topic World Foreign body detection

Detecting foreign objects in food and beverages is a critical step in ensuring the safety and quality of the products we consume every day. Whether through metal detectors, X-ray systems or optical detection methods, foreign object detection protects us from unwanted and potentially dangerous objects in our food.