Enlightenment from HEUFT

HEUFT SYSTEMTECHNIK GMBH will be presenting innovative solutions for simply more product safety and efficiency on small and large filling lines at BrauBeviale 2016.

HEUFT Final View II CAP

HEUFT Systemtechnik GmbH

HEUFT Systemtechnik GmbH

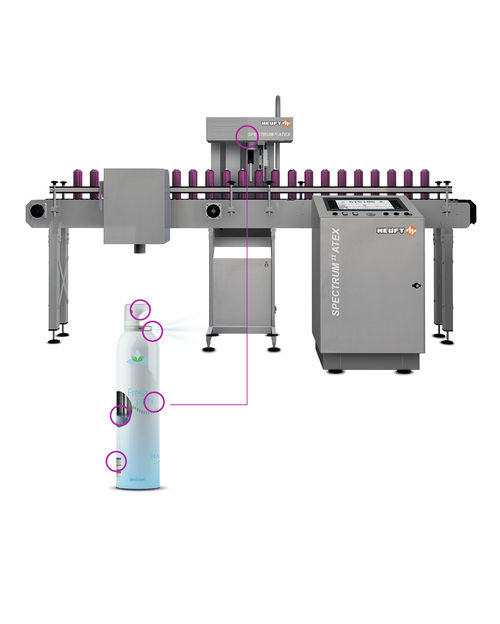

HEUFT Spectrum II ATEX

HEUFT Systemtechnik GmbH

What makes a good quality inspection? Can it also be integrated into small bottling halls? How do you keep the false rejection rate down without "overlooking" any critical faults? HEUFT will be providing enlightening answers to questions such as these at the BrauBeviale exhibition.

Compact and flexible solutions for quality check

The technology leader will clarify how to reduce product recalls effectively without thwarting line efficiency using SMEs by way of example in a special enlightenment area. You can even be treated to a beer created by HEUFT at a rotary system with HEUFT devices for an easy full container check, conveyor control system and fault rejector in a confined space. Furthermore compact and flexible solutions for a reliable empty bottle inspection will be presented for small filling plants in the new enlightenment area.

Leakage check and closure inspection of the new generation

The HEUFT SPECTRUM II device generation which offers simply more performance can also be experienced at BrauBeviale. Our new additions: the HEUFT FinalView II CAP for a complete all-around inspection of closures and the HEUFT squeezer II QS a leakage check for filled plastic bottles. They combine maximum automation and a self-explanatory audiovisual user guidance with an unprecedented precision when inspecting, tracking and rejecting containers as do all the systems based on the new platform. This provides maximum product safety, reduces the false rejection rate and at the same time saves valuable human resources. SIMPLY EASY – with HEUFT!

Most read news

Other news from the department business & finance

Get the food & beverage industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.