X-ray spot on fillet of pork

Stress makes meat bland and dry

A team of Swedish and German scientists has been using X-rays at the PETRA III synchrotron light source to study the decomposition of meat. In experiments carried out on fibres taken from fillets of pork, the researchers examined how the quality of the meat was affected by the storage temperature and by parameters affected by the amount of stress experienced by the pigs before slaughter. The results have been published in the journal Meat Science and are important for the way pigs are treated on the way to the slaughterhouse and for the handling of the meat after slaughter, but could also have implications for the conditions under which human donor organs are transported.

DESY/M. Schwartzkopf

The so-called water-holding capacity, WHC, is defined as the ability of meat to retain its natural water content. Water accounts for around 75% of the weight of fresh muscle tissue. This makes WHC an important indicator of the quality of meat. Water loss reduces the weight of the fresh meat to be sold and has a detrimental effect on its juiciness after cooking. Additionally, the lost water carries away proteins and salts with it, making the meat taste bland.

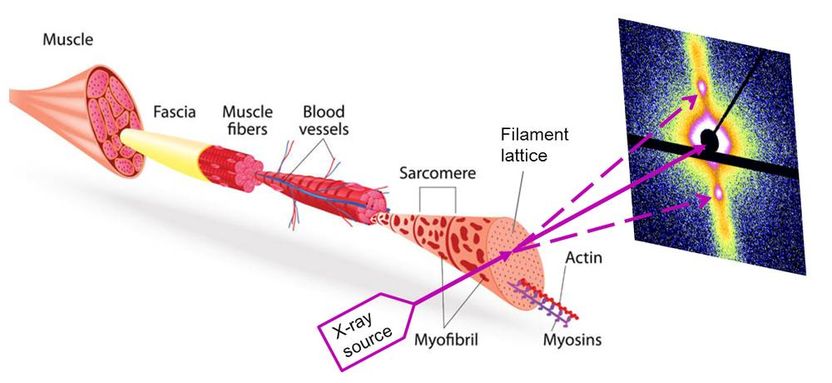

Most of the water in meat is stored within the contractile units of the muscle known as sarcomeres. A sarcomere is made up of proteins assembled to form contractile filaments. The distance between these filaments determines the ability to store water. Adverse conditions, such a stress suffered by the animal or inadequate refrigeration of the carcass during meat production, may cause the distance between the filaments to shrink, resulting in a lower water-holding capacity of the meat produced.

In their study, the scientists from the Karolinska Institutet in Stockholm and from DESY used bundles of fibres from the back muscles of Swedish domestic pigs. By altering the temperature and the pH of the samples, they simulated different conditions which may occur during meat production and which might potentially influence the water-holding capacity. “We wanted to know how refrigerating the meat after slaughter would influence the water-holding capacity,” explains Jiao Liu from the Karolinska Institutet. “Also, we simulated acidosis of the muscles, which can occur when pigs are subjected to too much stress during transport to the slaughterhouse.”

Having exposed the muscle fibres to elevated temperatures or an acidic environment, the scientists were then able to simultaneously examine for the first time how the separation and the structure of the sarcomere filaments changed in the meat, using the P03 beamline of the PETRA III radiation source. “We used micro-focussed small-angle X-ray scattering, SAXS, to observe how both the relaxed and the energy depleted rigor muscles changed before, during and after thermal or acid treatment,” explains Matthias Schwartzkopf, a scientist at the P03 beamline.

The results show that attachments are formed between the filaments during meat production, which have a direct effect on the water-holding capacity. This resulting loss of water is strongly favoured at higher temperatures and under acidic conditions. “For the production process this means that you should ideally cool the muscles from the 38 °C to 22 °C as quickly as possible before the onset of rigor,” says Liu.

“I hope the study will also have favourable consequences for the way in which animals are treated before slaughter,” Liu adds. “Stress on the way to the slaughterhouse may lead to acidosis of the animals’ muscles. Our studies suggest that this encourages the formation of attachments and thereby has a direct, negative impact on the water-holding capacity and hence the quality of the meat.”

In the long term, this study could have consequences not only for animal welfare during transport and the procedures used during slaughter, as a way of minimising water loss from meat and increasing the shelf life of meat. “The structure of human muscles is very similar to those of pigs. By understanding how meat tissue becomes degraded, we may also be able to achieve improvements in the handling of donor organs,” says Schwartzkopf.

Reference:

Rigor bonds cause reduced sarcomeric volume in skinned porcine skeletal muscle under PSE-like conditions, Jiao Liu, Matthias Schwartzkopf, Anders Arner, Meat Science Vol. 139, DOI:10.1016/j.meatsci.2018.01.014