World’s first 3D printed plant-based beefsteak invented

Giuseppe Scionti, Italian bioengineer and researcher in the field of Tissue Engineering, invented a unique technology that allows producing plant-based meat products with the texture and nutritional properties of animal meat products, using only natural ingredients of non-animal origin, and a 3D printer. This new invention combines tissue engineering and state-of-the-art knowledge in bioprinting with modern gastronomic strategies, creating a unique technology able to generate foods with high protein content and with the characteristic fibrous consistency of meat.

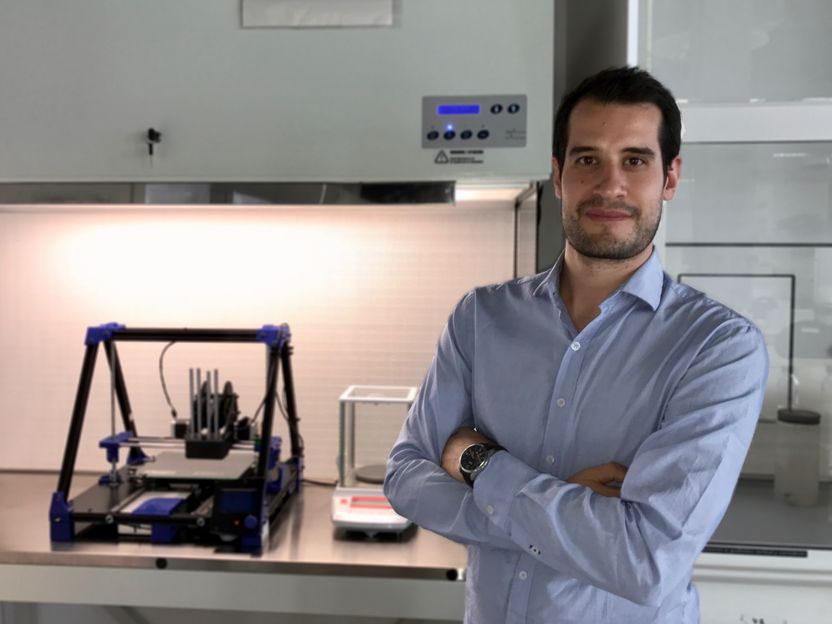

Dr. Scionti (left); plant-based beefsteak prototype (right).

Novameat

To bring this technology to market, Dr. Scionti founded NOVAMEAT, which is a startup aiming to provide new technological solutions to feed the planet’s growing population with plant-based products, overcoming the current unsustainable and inefficient livestock system by creating a healthy, efficient, humane and sustainable food supply. To achieve this vision, NOVAMEAT’s main mission is to produce and commercialize plant-based 3D printed fibrous meat products that are accessible, safe, scalable, and of high quality. NOVAMEAT's patented technology has the potential to allow producing 3D printed plant-based meat substitutes with the same texture, consistency, integrity, and appearance (at both the macro- and microscopic levels) of a variety of animal meat products. In addition, it has the unique advantage of permitting the use of a wide range of natural ingredients of non-animal origin, which allows selecting the appropriate ingredients to achieve products with the taste and the nutritional properties of a variety of animal meat products, such as beefsteaks and chicken breast meats.

The main objective of this novel technology is to produce alternative food to animal meat, to help reducing greenhouse gas emissions from livestock, which represent 14.5% of the total greenhouse gas emissions caused by man. The latest reports from the Food and Agriculture Organization of the United Nations (FAO) show that the current large-scale livestock breeding is no longer sustainable globally. For example, to get the same amount of calories from food, cattle's breeding requires seventy times more soil than what would be needed to grow fruit and vegetables. In total, livestock uses around 83% of the global farmland.

Assessing the growth trend of the world population over the next thirty years, we come to the conclusion that if we continue with the current system, in the future there will be little chance of having the resources to distribute food to everyone. It is for these reasons that finding another way of producing healthy and economical food that contains all the fundamental nutrients will help us to better manage our planet's food resources.

The invention of this new technology will be used not only to create an alternative to animal meat with benefits on the environment, but will contribute to solve the common problem of lack of certain nutrients such as essential amino acids, minerals and vitamins that are needed for a balanced diet. The goal is to improve the food nutritional content consumed in the rural regions of the planet. In fact, the products obtained by this technology can be sterilized and packaged, to be stored and transported to inaccessible areas that, due to long journeys, are not suitable for the correct food preservation. Moreover, the ongoing developments are evaluating the possibility to incorporate specific drugs into food products, in order to help those areas of the world where endemic diseases are present.

Although existing plant-based meat producers have managed to effectively replicate ground meats (see the Impossible Burger in the USA, for example), manufacturing plant-based meat products that can be a viable alternative to animal fibrous meats, such as beefsteaks, still represents an unsolved challenge. And although several companies around the world are working on the generation of artificial meat from animal cells cultured in the labs (also called cell-based meat), these strategies still possess inherent limitations in terms of time and costs of production.

The new technology patented by NOVAMEAT has the advantage of being able to generate different types of meat, not just ground meat. Moreover, already at this initial stage of development, our novel technology allows producing 100 grams of meat in half an hour, at a current manufacturing cost of 3 euros. For the large-scale production phase, the patent was designed to adapt to an industrial process that allows reducing both the time and the manufacturing cost by about one order of magnitude, compared to current values.

ABOUT GIUSEPPE SCIONTI: Giuseppe Scionti is a technology entrepreneur, inventor, and researcher in the fields of bioengineering and food tech. He currently focuses his activities on innovating the food system, through the development of new plant-based meat products at NOVAMEAT, of which he is the Founder and CEO. In 2018, he was featured by international mass media as the inventor of the world's first 3D printed plant-based meat substitute: his project at NOVAMEAT was featured on Bloomberg, Business Insider, CBS, Seeker, Mashable, EuroNews, Mirror, El Pais, The Spoon, and Food Navigator, among others. He was recently named as one of the "Nine Innovators to watch in 2019" by Smithsonian Magazine, in addition to being invited to speak at the European Parliament, the United Nations and TEDx events. Dr. Scionti and NOVAMEAT were included on Peter Diamandis' list “5 Big Breakthroughs to Anticipate in 3D Printing”.

Other news from the department business & finance

Most read news

More news from our other portals

Something is happening in the food & beverage industry ...

This is what true pioneering spirit looks like: Plenty of innovative start-ups are bringing fresh ideas, lifeblood and entrepreneurial spirit to change tomorrow's world for the better. Immerse yourself in the world of these young companies and take the opportunity to get in touch with the founders.