Osaka University, Shimadzu, and SIGMAXYZ collaborate on 3D Bioprinting technology

Accelerating technological development to solve social issues such as the environment, food, and health

National University Corporation Osaka University, Shimadzu Corporation, and SIGMAXYZ Inc. have signed an agreement on collaboration for "social implementation of 3D bioprinting technology." Prior to this, Osaka University and Shimadzu Corporation also signed a joint research agreement on the development of automated production equipment for tailor-made cultured meat using 3D bioprinting.

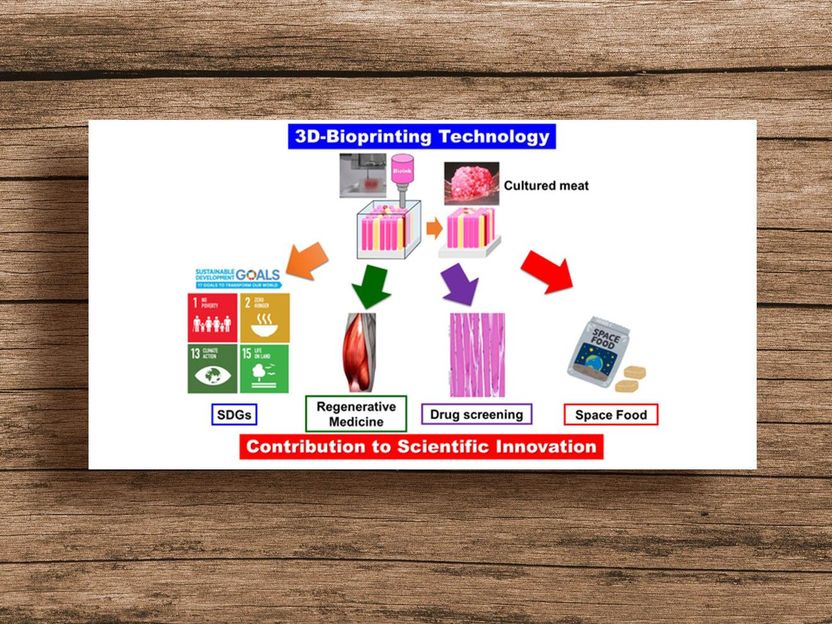

Scientific and technological development based on 3D printing technology

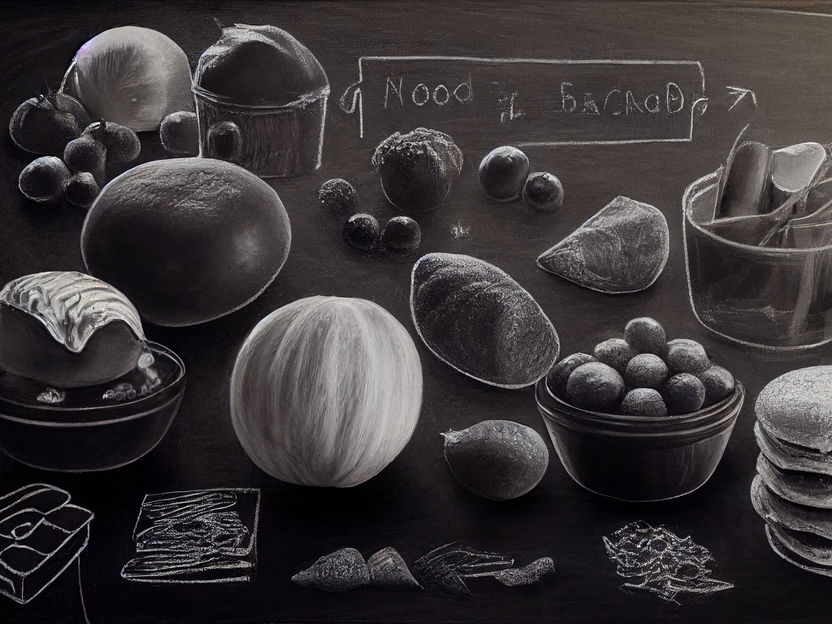

Osaka University

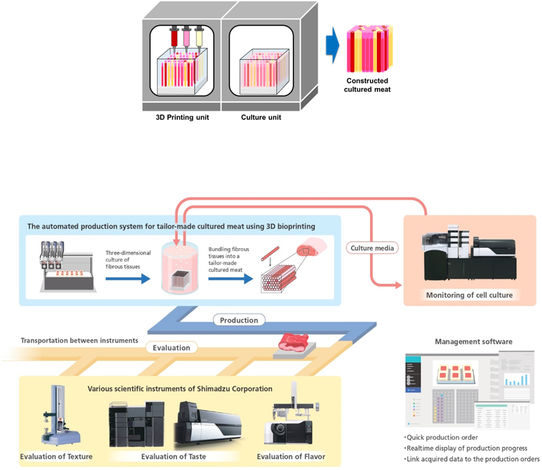

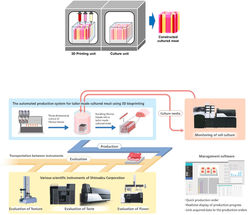

Illustration of an automated tailor-made cultured meat production device by 3D bioprinting

Osaka University and Shimadzu Corporation

Through this collaboration between Osaka University, which is researching 3D bioprinting technology, Shimadzu Corporation, which is engaged in analytical and measuring instruments including automated pretreatment systems, and SIGMAXYZ, which has strengths in consulting and ecosystem building in the food tech field, the three parties will work together to develop a new food tech ecosystem that will enable the development of new food products and services that will be of value to consumers. Through these activities, the three parties aim to contribute to solving environmental and food problems, improving people's health, drug discovery, and the evolution of medicine.

Development of automated production equipment for tailor-made cultured meat using 3D bioprinting

This 3D bioprinting technology was developed by Professor Michiya Matsusaki of the Graduate School of Engineering at Osaka University to create muscle tissue structures. This technology is expected to be utilized in the fields of food, regenerative medicine, and drug discovery, including "cultured meat with controlled arrangement of muscle, fat, and blood vessels" and "models of athletic organs and internal organs using human cells.”

Most of the cultured meats reported so far have a minced structure consisting only of muscle cells, making it difficult to reproduce complex structures. To solve this problem, Matsusaki and co-workers developed a 3D bioprinting technology that uses 3D printing to produce different fibrous tissues (muscle, fat, and blood vessels) and integrates them into a bundle. This technology has made it possible not only to reproduce the beautiful "sashi" of Wagyu beef, but also to delicately adjust the fat and muscle components. Osaka University and Shimadzu will jointly develop equipment to automate the production of cultured meat using this technology.

Collaboration for social implementation of 3D bioprinting technology

In addition, the three parties will collaborate to promote the following activities:

- Joint research with other companies to promote the development of 3D bioprinting technology.

- Collaboration with companies and organizations with peripheral technologies and know-how.

- Collaboration with companies and organizations in the meat supply chain.

- Dissemination of information about 3D bioprinting technology to society.

In promoting each activity, each of the three parties will play the following roles:

Osaka University will continue its efforts to develop tissue engineering technologies, including 3D bioprinting. The 3D bioprinting technology developed by Matsusaki is a unique technique to construct muscles and motor units in vitro by bundling muscle, fat, and blood vessel fibers, but it is difficult to reproduce more complex tissue and organ structures. In addition, although it is now partially possible to deliver culture media and drugs externally via blood vessels, it is difficult to maintain large organ models for long periods of time, something that is still a major challenge worldwide. Therefore, based on our knowledge of tissue engineering and 3D bioprinting, we will focus on developing the basic technologies to realize new "reconstruction of complex tissue/organ structures" and "long-term culture of organ models by circulation of nutrients and oxygen through blood vessels."

Shimadzu has provided an extensive selection of analytical and measuring instruments and technologies to a wide range of industries. The movement to add new functionality to food products has picked up steam in recent years due to growing health consciousness, and Shimadzu has been enhancing not only its instruments but also the software and databases required in each process, from the research and development stage to quality control to ensure safety and security. We are also engaged in joint research with the National Agriculture and Food Research Organization to analyze the functional components of agricultural products. In recent years, we have also focused on the development of equipment and technology to automate and streamline the cell culture process through AI and robot technology. We will utilize these technologies, products, and knowledge to develop an automated production device for cultured meat using 3D bioprinting technology.

Shimadzu's role through this collaboration is to "automate cultured meat production using 3D bioprinting technology" and "provide analysis and measurement technology related to cultured meat development." The former is the development of specialized equipment to automate the process of bundling muscle, fat, and blood vessel fibers obtained by 3D printing technology into a steak-like structure, while the latter is the development of solutions to analyze not only items related to "palatability" such as taste, texture, flavor, and chewiness, but also "functionality" such as nutritional content. The company is also looking to utilize 3D bioprinting technology in the fields of regenerative medicine and drug discovery, for example, by developing production technology for cultured meat using 3D bioprinting technology to create human organ models, thereby replacing animal experiments. This will enable research on rare diseases and application to personalized medicine. In this way, Shimadzu will explore not only cultured meat as a food source, but also its potential in medicine and drug discovery.

SIGMAXYZ will serve as the program management office for the social implementation of 3D bioprinting technology, leveraging its advanced program management capabilities cultivated through its consulting business and its alliance network with various companies, including those in food tech circles. Its role as aggregator will be to formulate policies for each theme of the technology application, coordinate with companies and organizations that possess peripheral technologies and know-how that may be required for each theme, and promote the creation of frameworks, progress management, and issue management for each initiative, thereby contributing to this collaboration.

3D bioprinting technology can help solve food and environmental problems by utilizing animal cells to produce cultured meat. It also has great potential to solve social issues such as regenerative medicine and drug discovery by utilizing human cells. Osaka University, Shimadzu Corporation, and SIGMAXYZ will accelerate the implementation of this technology in society by utilizing it together with various companies and are committed to creating a more prosperous future.