Researchers develop efficient process for chemical terpene synthesis

Potential applications in food, cosmetics and pharmaceutical industries

A team of scientists led by Professor Tanja Gulder at Leipzig University’s Institute of Organic Chemistry, together with colleagues from the University of Regensburg, has developed a simplified and efficient method for the artificial production of terpenes. Terpenes are a very extensive and diverse class of natural products that perform a wide range of functions in nature and are also used industrially. Until now, producing them has required a wide variety of starting scenarios, some with harsh conditions, or has been based on substances taken from nature. The new method, on the other hand, follows a flexible and resource-saving modular principle. This allows the targeted production of these important natural substances from simple and readily available starting materials. To do this, the team replicated naturally occurring enzymatic processes using fluorinated alcohol / catalyst solutions. The method can be used widely in existing laboratories. The research findings have now been published in “Nature Communications”.

In the illustration, the catalyst – the cat – gives a carbon chain a persistent form, which is represented by the clamps. In reality, the strongly binding solution acts as a catalyst in which hydrogen atoms have been replaced by fluorine atoms. The “glue” is the reaction.

Dr. Christoph Selg

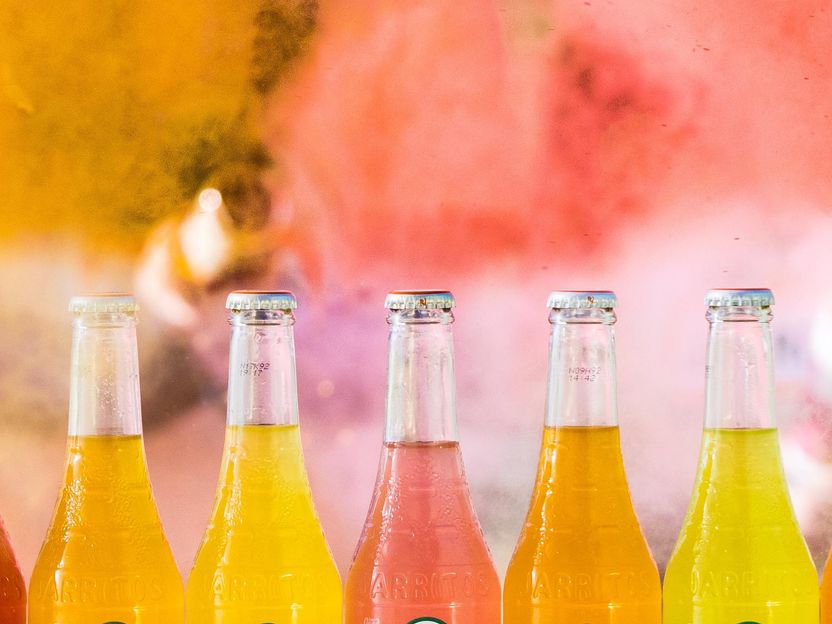

Terpenes are what give pine needles their scent, and beer and orangeade their taste. They play a key role in how living things like insects, but also we humans, communicate, and in defence mechanisms, for instance in plants against animal predators, fungi and bacteria. In human biology, terpenes also play an important role in metabolic processes.

Terpenes have long been used industrially on a large scale: in the production of foodstuffs and food supplements, in perfumes, and in pharmaceuticals, such as cancer and COVID-19 drugs. “We need quite a lot of tonnes of a wide variety of terpenes every year, and that means we also have to be able to produce them synthetically in an efficient and sustainable way – and that’s a big problem,” says Professor Tanja Gulder, who holds the professorship for Biomimetic Catalysis at Leipzig University.

In nature, enzymes form terpenes through targeted folding

“Nature has a unique way of making each of these molecular compounds,” says Gulder. “This involves the use of so-called terpene cyclases, proteins with 100 to 1,000 amino acids. These enzymes press simple and mobile carbon chains into a specific three-dimensional form that determines the appearance of the product,” Gulder adds. Once the reaction has taken place, the shape of the respective terpene remains unchangeable. The reaction takes place in what is known as an enzyme pocket in the active centre of the enzyme, which carries a blueprint of the form to be produced. After the reaction is complete, the enzyme releases the finished product and the process is repeated with the next building block. “It can be thought of as a fast-moving molecular manufacturing machine,” says Gulder.

There are terpenes that are similar in terms of the type and number of their atomic compounds – but whose spatial arrangements are different. “In a simple case, such atomic differences determine whether something tastes like caraway or orange,” says Gulder. However, such differences could also mean that one terpene acts completely differently in the human organism than the other. Errors here can have fatal consequences. “And depending on the way the carbon chains are put into the enzyme pocket, different terpenes come out, which is also part of the complexity in nature,” explains Gulder.

Extraction difficult so far

The researcher points out that previous approaches to recreating terpenes in the lab required very different and harsh initial conditions, such as a highly acidic environment or low temperatures, adding that this is neither effective nor environmentally friendly for large-scale production. The extraction of terpenes from organisms such as plants, animals and fungi has also reached its limits. “You can’t cut down all the Pacific yews to isolate taxol for a cancer drug. It would take the bark of twelve mature specimens of this not-very-widespread tree species to make one gram of the active ingredient,” says Gulder. At the moment, a precursor of the desired terpene is extracted from needles of another tree species and then processed further. “So we wanted to see how we could replicate nature’s processes in a test tube and achieve the greatest possible flexibility and efficiency.”

The solution: Liquid construction kit with fluorinated alcohol

The team succeeded in building a custom-fit, enzyme-like environment for the formation of terpenes, consisting of readily available chemical substances. This can work like a construction kit: by adding different starting materials and additives that act as catalysts, different terpenes can be produced artificially. At the heart of the new approach are the properties of fluorinated alcohol: “We had found that when hydrogen atoms in alcohols were replaced with fluorine atoms, the resulting fluorinated alcohol exhibited extreme bonding forces. In such solutions, molecules form helices or rings that stack up to form tubes,” explains Professor Gulder. By adding chemicals, it is possible to influence the size and shape of these structures. “Basically, we have built an artificial enzyme pocket in the form of a structured solution into which our respective starting material can fold. As in nature, forms persist after the reaction.”

Computer simulations were also used to develop this new method. Professor Tanja Gulder explains: “Our colleagues Philipp Dullinger and Professor Dominik Horinek of the University of Regensburg calculated which three-dimensional structures, so which shapes, the alcohols form with the additives used in each case. This was important to identify suitable catalysts that would lead us to the desired terpenes.”

Realisable in standard chemistry laboratories

The method does not require any additional infrastructure, it can be applied in chemistry laboratories at no additional cost, and can be easily scaled up for application to large-scale production. What is more, the process requires no heavy or precious metals. “This makes it broadly applicable and more sustainable than previous methods,” explains Gulder, who was previously a Heisenberg professor at the Technical University of Munich. “It is an example of the forward-looking research focus on multifunctional catalysis at Leipzig University, and at the CTC major research centre that has just been approved in the Leipzig area.” Its focus will be on sustainable catalysis in an industrial context.