The physics of gummy candy

Dozens of ingredient and storage combinations reveal what factors make some gummies harder than others and how product formulation affects shelf life

Advertisement

For gummy candies, texture might be even more important than taste. Biting into a hard, stale treat is disappointing, even if it still carries a burst of sweetness. Keeping gummies in good condition depends on their formulation and storage, both of which alter how the molecules in the candies link together.

Gummy candy as a food model for texture

Suzan Tireki

In Physics of Fluids, by AIP Publishing, researchers from Ozyegin University and Middle East Technical University conducted a series of experiments that explore how changing key parts of the gummy-making process affects the final product, as well as how the candies behave in different storage temperatures. They used these results to identify the most shelf-stable combination for gummy candies.

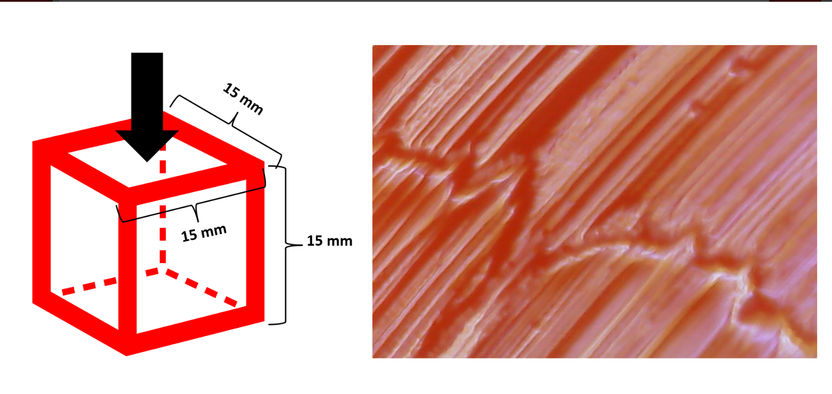

To tackle these questions, the group adjusted a variety of inputs while making the gummies, from the glucose syrup-to-sucrose ratio to starch and gelatin concentrations. They wanted to understand how these changes affected features like candy texture, moisture content, and pH.

They then studied the resulting features of the candies before and after storage. Storage conditions varied from 10 to 30 degrees Celsius for 12 weeks or 15 to 22 C for a year.

Such extensive combinations of procedures presented their own hurdles during the study.

“A high number of parameters was the main challenge in our study,” author Suzan Tireki said. “We had eight different candy formulations, four different temperature conditions, and two different storage times. Another challenge was to try to find a common model for all these eight formulations, as each of them behaved differently.”

To account for such a variety of variables, the researchers used a statistical model to describe how each combination affected the quality parameters of the gummy. They specifically explored the chemical crosslink distances, or the length of bonds between molecules in the candy.

“The most innovative part of our study was investigating the texture of the gummy candies by estimating the average crosslink distances using the hardness data coming from texture profile analysis,” Tireki said.

The moisture content and pH, for example, were heavily dependent on the glucose syrup-to-sucrose ratio, whereas the gelatin content affected crosslink distances.

“Our most surprising finding was that hardness and average crosslink distance were not affected by the amount of starch,” Tireki said.

Identifying the most stable combinations for gummies can extend shelf life and improve candy quality in different climates and across the food industry.

The researchers next look to explore the role of plant-based formulations, mold shapes, and packaging types.