Krones’ concept for block-synchronising blow-moulder, labeller and filler is a success story

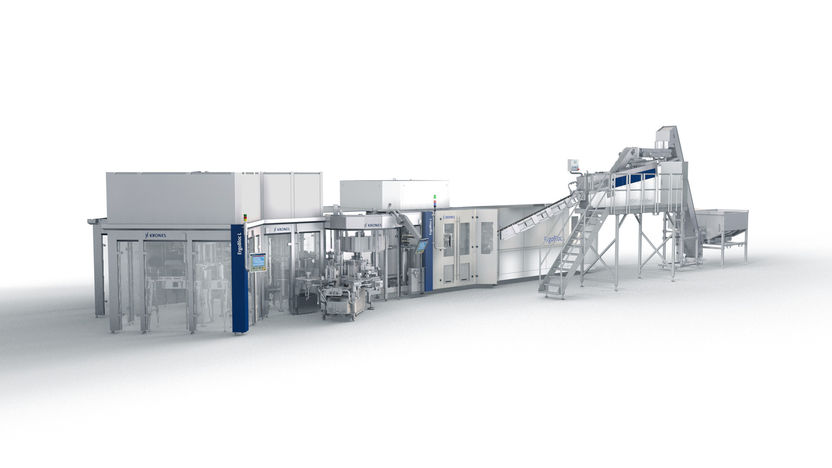

Producing, labelling and filling PET containers – all in a single machine. That’s the concept behind the Krones ErgoBloc L. This idea, to block-synchronise the blow-moulder, the labeller and the filler, has definitely caught on. At the drinktec in 2009, Krones had surprised the Beverage Industry with this design. Today, we can justifiably speak of a veritably triumphal progress by the ErgoBloc L: in May 2015, Krones booked an order for the 100th ErgoBloc L. FINE Bio from South Korea will be using the round-number machine.

KRONES AG

KRONES AG

The entire wet end in a single machine

ErgoBloc L means nothing more and nothing less than that the entire wet end of a beverage bottling line is grouped together in a single machine. The ErgoBloc L does without conveyors entirely; this guarantees a controlled process, scoring highly in terms of flexibility, reproducibility of change-overs and correspondingly high effectiveness. For the first time, it was thus possible to efficiently run an entire wet end with just one operator, and at the same time to reduce the requisite footprint by up to 30 per cent compared to a conventional block.

The ErgoBloc L enables its users to run their production operations effectively on a minimised area, to improve their sustainability by reducing their consumption of energy and media, and to encounter fewer malfunctions than with conventional systems. Thanks to the Contiform 3’s mould quick-change system, clients can change over to a different product within a minimised timeframe. The containers are filled and labelled without any problems, supervised by only a single operator. The ErgoBloc L is also predestined for flexibly implementing a reduction in bottle weight.

Continual optimisation

Krones would not be Krones, if despite its success the concept were not being continually improved. Now, for example, the transfer housing between the labeller and the filler has been design-enhanced to reflect the latest state of the art. The aseptic module previously used has been discontinued, because it emerged that in actual everyday operation it was not usually needed. This renders the transfer not only more affordable, but also more aesthetically attractive.

The base post-cooling function, too, which is necessary when CSDs are being bottled, has been modified. Upstream of the labeller, the container’s base is cooled with air, downstream of the labeller with water. For air-cooling, Krones now uses a cooling blower instead of compressed air. This reduces the compressed-air requirement massively, cutting the costs involved by more than 10,000.00 euros a year.

In order to save further costs, the construction of the labeller itself has been altered. Hitherto, a modularised labeller was always used as a link between the blow-moulder and the filler. The thinking here was that it offers a high degree of flexibility in the choice of labelling mode. But practical experience has shown that in most cases this is really not necessary. In the overwhelming majority of all lines, the owners of the ErgoBloc L run wrap-around labelling. So in the future, the machine will specialise on a Contiroll station, thus achieving significant cost savings.

Up and running worldwide

The output ranges between 27,000 and 82,000 containers an hour, depending on the bottle size and the product involved. ErgoBloc L layouts are meanwhile the predominant choice for still water (in up to 60 per cent of cases), and are being used for carbonated waters and soft drinks in around 40 per cent of cases. The systems are up and running all over the world, chiefly in the Asia/Pacific region and in the USA. But ErgoBloc L systems are likewise much in demand in Italy, Spain, Poland, in the Arab Emirates, in Lebanon and in Mexico, Ecuador, Russia, and also in Germany and Africa.

The South Korean client FINE Bio will be able to use the 100th ErgoBloc L manufactured by Krones as from early 2016 at its facility in Jirisan National Park, where it will then possess the most modern and compactly dimensioned bottling concept for CSDs and still water.