COPA-DATA at BrauBeviale 2015: Ergonomic software for the Smart Brewery

COPA-DATA, manufacturer of ergonomic automation software for the Beverage Industry, will attend this year's BrauBeviale in Nuremberg where it will be illustrating how the zenon Product Family is already supporting the Smart Brewery today. This includes the networking of all production areas, comprehensive line management, batch control for creative brewing processes, OEE monitoring, and optimized energy consumption. Booth visitors can also test the HMI Multi-Touch technology for industrial environments first hand, and can gain an overview of smart system architectures; connecting zenon data from sensor right up to the cloud.

Copa-Data Brau Beviale 2015

COPA-DATA Headquarters

Bild: Ing. Punzenberger COPA-DATA GmbH

Bild: Ing. Punzenberger COPA-DATA GmbH

Industry 4.0 offers great opportunities and challenges for drinks producers: ensuring competitiveness, resource and energy efficiency, quick adaptation to sales markets and increasing individualization. But what characterizes the smart brewery of the future? It can link local, intelligent systems to digital networks of machines and product components. It independently records data from its environment and then uses this within the production process. Production will thus become more flexible, small lot sizes can also be produced profitably, and predictive maintenance is organized by the machine itself. The ordering of materials and consumables, and even energy management, are becoming progressively more automated. Machines that are designed to communicate with different applications contribute to this. As does software that can intelligently connect these machines and offer the human an ergonomic working environment.

Learn how to use the evolution of Industry 4.0

Just as beverage production needs to be open and flexible, so should be the software for process and visualization. "Our software zenon is highly versatile and is preparing beverage manufacturing for the evolution of Industry 4.0," explains Emilian Axinia, Industry Manager for Food & Beverage at COPA-DATA. "With zenon we're offering a comprehensive toolbox for consistent and ergonomic production, filling and packaging processes. The software thereby operates like a brain, linking individual system functions intelligently with one another."

Emilian Axinia and his team will demonstrate the smart architecture of zenon at booth 515, hall 7. The information flow is far-reaching – from machine sensor data right up to cloud applications and mobile devices. Various server and client models can be deployed. "The variety of interfaces and simple implementation, particularly with existing production equipment, impresses our customers again and again," says Axinia.

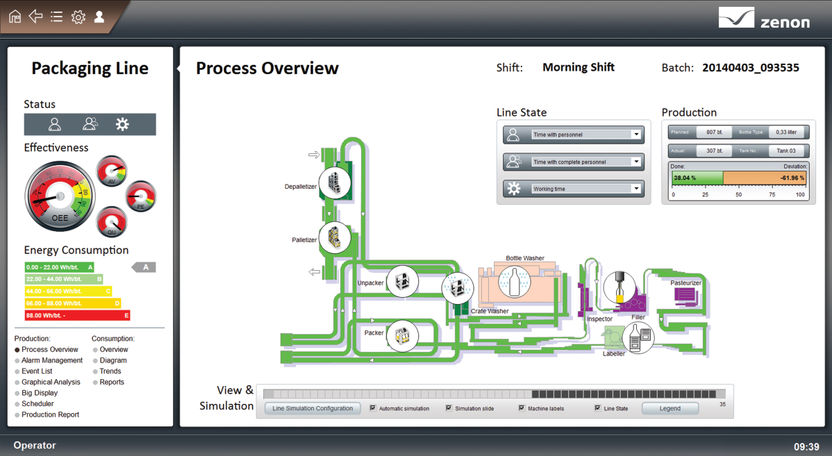

zenon for Line Management and OEE

Companies that implement zenon for line management can guarantee a continuous information flow – from the machine to the ERP system and back. They can ensure the efficient use of the raw materials as well as the equipment, fulfill quality and time standards for all their production orders, and are reducing costs in the long term and on a sustainable basis. COPA-DATA offers a universal, flexible and open platform with zenon, that is geared to contribute to an increase of Overall Equipment Effectiveness (OEE). Companies with several locations can count on zenon's reliability and adaptability for Roll-out Projects.

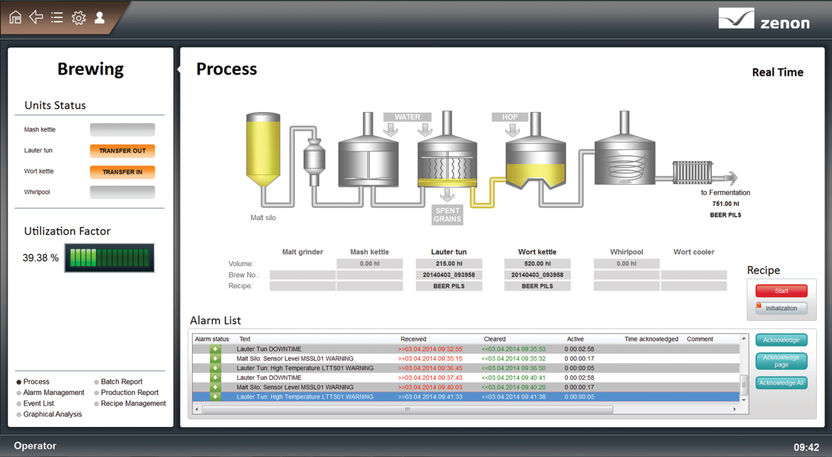

zenon for the Management of creative Brewing Processes

Breweries that implement the zenon Product Family can fully display, comprehensively monitor and efficiently control their beverage production. Here, zenon can particularly support the production process: the Batch Control Module allows processes in a batch-based production to be optimally controlled and monitored as well as ensure an unchanging high quality. Even smaller lots, common for craft beer recipes, can thereby be flexibly mastered. Brew masters can create and manage master recipes with Batch Control. These then serve as templates for the control recipes used in beverage production.

zenon for Energy Management

An energy management system is efficient if energy data is recorded in an automated manner, shown with a clear overview and is easy to analyze. zenon corresponds to the defined requirements of the "Certified Energy Management" standard set out by TÜV SÜD and meets the requirements from chapter 4.6.1 – monitoring, measurement and analysis – of ISO 50001. With zenon, the complete information flow of an energy data management system (EDMS) can be configured consistently, openly and flexibly. EDMS thus becomes scalable and sustainable. Higher-level management systems can also be simply integrated at a later time. In dynamic production landscapes too, the software adapts to new conditions with minimal effort and thus additionally minimizes the costs of future reconfiguration or replacement. Furthermore, zenon supports the individual roles of the employees involved with the process, with tailor-made information, such as real-time indicators or historical reports, precisely when and where they are needed, providing the required level of detail.

zenon for HMI

Another focus for COPA-DATA at the BrauBeviale 2015 is the implementation of zenon as software for HMI operation. The user-centric HMI usability and the high level of connectivity due to over 300 pre-installed drivers distinguish zenon. Multi-Touch technology is completely integrated here. It allows intuitive handling, a minimal amount of training and induction, and increased operating safety thanks to two-handed operation and gesture-based login. Furthermore, zenon-controlled machines are simple to integrate in larger systems right up to ERP and quick to extend, by means of the zenon software family, to the areas of SCADA and reporting. Visitors at the booth can gain a first-hand impression of the possibilities of zenon for HMI operation.