Making cereal bars is a piece of cake for McVities

When a fully automated, accurate and reliable batch mixing and continuous weighing plant was required, Gericke provided the solution.

The need to install a flexible manufacturing facility to handle various differing recipe types and also have the ability to increase and decrease the throughput to match packaging rates demanded an innovative approach for the McVities Tollcross site near to Glasgow.

Extracted Sack Tip Assembly

Source: Gericke AG

GMS705 litre “Multi-Flux®” Cross Flow Mixer

Source: Gericke AG

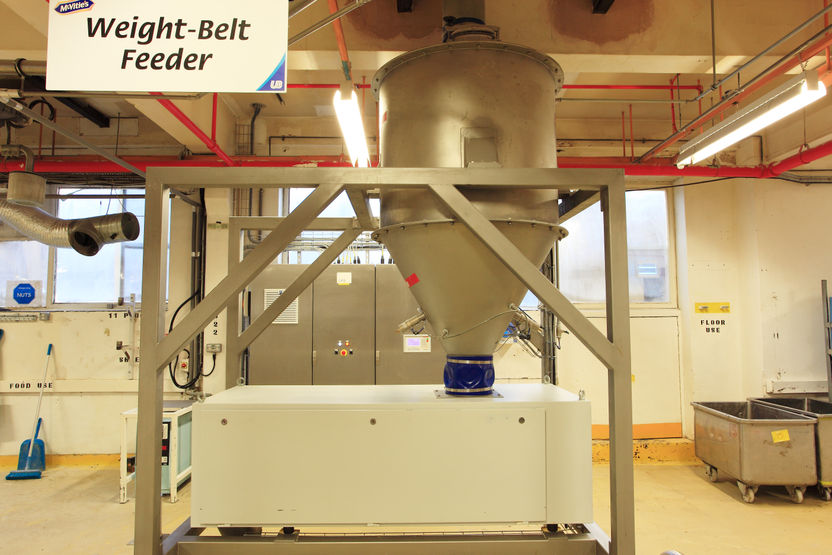

Gericke DBW 400 Weigh Belt Feeder

Source: Gericke AG

Vacuum Receivers

Source: Gericke AG

Vacuum Receiver with Volumetric Feeder

Source: Gericke AG

Gentle handling of the ingredients and hygiene is key to the success of this process and with the prospect of many recipe changes over a short period the equipment employed must be suitable for complete and fast cleaning between campaigns.

Improved efficiency and management control of raw material additions prompted McVities to specify a fully automated plant control system which provides “real time” data of the process parameters.

Production of high quality added value confectionery products with varying recipes is a complex process which demands weighing tolerances of the highest accuracy, especially for minor ingredients.

Initially the various process steps were identified including the methods of ingredient reception, batch preparation, weighing tolerances, product screening and transportation.

Trials

Extensive pilot trials were undertaken at the Gericke test laboratory to ensure the correct selection and optimisation of the equipment. Process and plant layout work began during the selection stage to determine the optimum configuration of the plant within the existing building dimensions including access and maintenance of the equipment.

The raw materials which include oats, crispies, sultanas, nuts and flakes are assembled in a batch preparation and tipped into a reception hopper.

Minor ingredients are tipped into a separate sack tip station which includes extraction to protect the plant operatives and reverse jet filter to maintain a dust free environment around the tipping area.

The material is screened and metal checked prior to entering a Gericke type GMS 700 litre batch mixer. This unit uses the “Multi-Flux” cross flow method which employs twin counter rotating paddles to create a “fluidised zone” in the mixing chamber in which approximately 80 per cent of the mixing occurs.

This mixing technology is fast and efficient with blending times typically 90 seconds to 3 minutes producing a high quality homogeneous blend.

Due to the relatively low power consumption compared with other mixer types the energy transfer into the product is minimal and this in conjunction with the design of the paddle produces a gentle mixing action ensuring that degradation of the particles is minimised.

The blender includes a variable speed drive which adjusts the speed of the paddles and therefore optimising the mixing action to suit the characteristics of the various ingredients.

The entire batch is then rapidly released into a surge hopper in order that the mixer can be refilled whilst the previous recipe is processed downstream therefore maximising the utilisation of the plant.

At this point the system converts to a continuous process and a Gericke gravimetric weigh belt feeder controls the rate of the material into a vacuum pneumatic conveying system. As the material is conveyed along the belt it passes over a load cell which measures the instantaneous throughput of the mass and adjusts the speed of the belt to control the flow within specified tolerance.

The vacuum transfer system conveys the material at low velocity to a continuous mixer for the addition of the liquid binding agent.

The vacuum exhauster includes a variable speed drive to reduce the airflow to the minimum required to entrain the product therefore reducing the risk of segregation and product breakdown. One of the recipes includes Ginger which is heavily flavoured and a separate system is used to transfer this ingredient from sacks to the mixer in order to eliminate cross contamination in other recipes.

A fully extracted sack tip assembly is used to accept 25kg sacks and a separate vacuum transfer system conveys the flavour to a volumetric screw feeder which meters the ingredient directly into the mixer.

Hygiene

Fast changeover together with the ability to clean all areas of the equipment internally is extremely important and all equipment was designed for easy access. The mixer included side and top cleaning ports and the rotary valves are the FCT fast clean version which allows the rotor to be fully extracted with no need for special tools.

The weigh belt feeder includes the fast belt changeover system where the belt mechanism is drawn outside of the machine to allow full access to the working components.

Safety

Safety issues were addressed by a comprehensive risk analysis of the entire plant taking into account the potential for a dust explosion and also identifying other potential hazards within the operating sequence.

The scope of Gericke’s supply included: the project management; design; manufacture; procurement; mechanical and electrical installation; control; commissioning and operator training.

Phil Griffiths, Project Engineering Manager at McVities commented that the principle reason for the selection of Gericke as the main contractor for the project was their proven ability to supply single source turnkey installations, the opportunity to undertake trials in a UK based test facility and their flexible approach to engineering the best solution for the application.

Turning the concept into reality at McVities took into account the many requirements of a modern production facility underwritten by over 122 years of experience from Gericke.