Nomad Foods Urges Food Industry to Adopt End-to-End Carbon Impact Product Assessment to Help Tackle the Climate Emergency

Fully understanding food waste in the product life cycle is vital for reducing carbon emissions

Nomad Foods, Europe’s leading frozen food company, which owns brands including Birds Eye, Findus and iglo, is calling on the food industry and regulators across Europe to consider a more comprehensive, end-to-end approach to life cycle assessment (LCA) studies, which includes food loss and waste impacts, to improve transparency for consumers and drive critical action to reduce carbon emissions.

Graphic: Business Wire

Graphic: Business Wire

Food production is a major contributor to climate change and making better environmental choices about what we eat and how we reduce food waste is one way for businesses and consumers to lower their carbon impact. To support this action, it’s vital that food companies fully understand their products’ total emissions footprint and provide clear, accurate and complete information.

With carbon labels and previous LCA studies on food often limited in scope, Nomad Foods has recently enlisted the help of international experts in impact assessments, PRé Sustainability, to conduct a unique end-to-end LCA study for 22 of Nomad Foods’ most popular products1.

Crucially, the study went beyond the scope of existing LCAs to include all stages of the product life cycle, incorporating new data on retailer and consumer food waste (an important element of Scope 3 emissions for food manufacturers) and primary data for all processing steps, improving the accuracy of the assessment – with the results peer reviewed by leading experts.

The study showed that retail and consumer food loss and waste – data which is not generally included in previous LCA assessments of food – plays an important part of the product life cycle and has a significant effect on a product’s overall environmental impact. In fact, retail and consumer food waste equates to an estimated 160m tonnes and 17.25m tonnes of CO2 in the EU and UK respectively2.

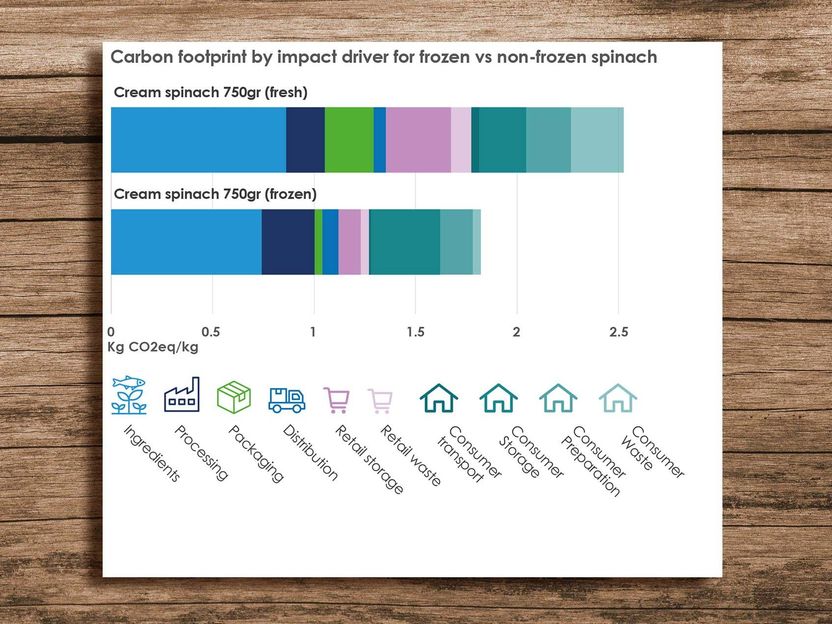

This new assessment means that, for the first time ever, clear conclusions can be drawn about the carbon footprint of frozen foods products and meaningful comparisons made to their non-frozen alternatives, while accounting for all relevant and material impacts. Results for the 22 frozen products assessed under the new study showed that most had an equal or lower carbon footprint than similar products using other preservation methods.

Stéfan Descheemaeker, Chief Executive Officer, Nomad Foods, said: “Consumer demand for nutritious, high-quality, sustainable food is growing and we believe it’s vital that we find ways to provide consumers with information that helps them make informed choices and provides confidence that sustainability claims are robust and evidence-based. To support this, we encourage the food industry, retailers and regulators to adopt a wider scope for LCAs as standard, taking the whole product life cycle into account. Based on the ground-breaking work that our teams have undertaken with life cycle experts PRé Sustainability, we can see there are significant benefits to frozen food in terms of longer-term food preservation and reduced food waste.”

Ellen Meijer, Consultant, PRé Sustainability, said: “This is one of the most elaborate frozen food LCA studies ever done, covering not only a wide range of frozen food products and their alternatives, but also approaching them all in a consistent methodological manner. Combined with the large amount of primary production data included and the attention to detail at each stage, this study is one of a kind. Based on this study, we are now in the unique position to draw conclusions about the carbon footprint of frozen food products compared to their non-frozen alternatives and generalize these conclusions across the frozen food category."

1The comprehensive LCA study covered 10 keys stages. Stages 6 – 10 are the extended scope of the assessment not generally included in other studies:

- Ingredients: Production, including transport to factory.

- Processing: All activities that happen at the factory including energy, on-site waste and the treatment of it, and activities related to packaging the product. Also includes any pre-blanching or pre-freezing before it reaches the factory. The study included primary data for all material processes improving the accuracy of the assessment.

- Packaging: Packaging materials, including their transport to the factory.

- Distribution: Transport from the factory, storage at the distribution centre, transport to the retail hub and storage at the retail hub.

- Retail storage: Electricity and coolant use in the retail cold room and on the retail floor.

- Retail waste: Waste treatment of transport packaging, product losses and waste treatment of product losses, including processing, packaging and distribution of the product losses.

- Consumer transport: From the retailer to the consumer.

- Consumer storage: Electricity use for storage at the consumer.

- Consumer preparation: Energy use at the consumer to cook the food product, as well as any capital goods.

- Consumer waste: Waste treatment of primary packaging and product losses. This includes all upstream processes required to compensate for the product losses at the consumer.

26.9m tonnes of the UK’s annual total of 9.5m tonnes of food waste is down to the retailer and consumer, equivalent to 17.25m tonnes of CO2 (WRAP). In the EU the retail and consumer proportion of the 88m tonnes of food waste generated, equates to 160m tonnes of CO2. Calculation based on 1 kg of food waste creates 2.5 kg of CO22013; Food Wastage Footprint Impact on Natural Resources; United Nation’s Food & Agriculture Organization