Safeguarding coffee grinders from hidden stones

Most coffee connoisseurs are familiar with the gentle hum of their favourite café’s grinder while they wait in eager anticipation of that aromatic first sip. But behind this everyday scene lies a surprisingly tricky problem. Coffee beans often come mixed with small stones—accidental stowaways from harvesting and processing. Nearly identical to beans in size, shape, and colour, stones routinely evade even the most meticulous of inspections.

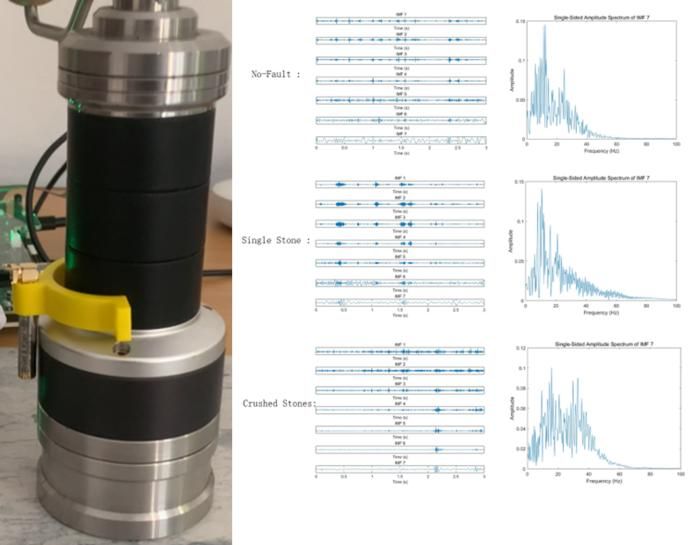

Setup of the system and graphs showing the accuracy of acoustic method developed to detect hidden stones among coffee beans Credit

SUTD

For cafés and commercial coffee producers, stray stones spell trouble. When they enter the grinding mechanism, they can severely damage the grinder’s precision-engineered cutting discs known as burrs. These burrs, essential but highly expensive, require expert alignment after replacement, which often disrupts operations and therefore imposes considerable downtime.

“Large-scale factories rely on advanced screening methods early in coffee production. Due to the size and cost constraints, these traditional screening methods aren’t practical for most busy cafés and smaller commercial settings,” said Dr Teo Tee Hui from the Singapore University of Technology and Design (SUTD).

Motivated by this industry challenge, Dr Teo and his team set out to develop a solution based on sound—quite literally! Their method involves a microphone placed strategically within the grinder. As beans tumble through and the burrs begin their rotations, the microphone captures the machine’s acoustic profile in real time. In particular, a stray stone trapped amongst the beans produces a distinctive acoustic signature, different from the softer sounds of beans alone.

The team’s findings were published in the paper, “Innovative EMD-based technique for preventing coffee grinder damage from stones with FPGA implementation.”

The centrepiece of their method is an algorithm called empirical mode decomposition (EMD), which breaks down complex sound signals into simpler components known as intrinsic mode functions (IMFs). By isolating these IMFs, the team’s system can accurately pinpoint the presence of stones. The team’s innovation is further enhanced by implementing this algorithm on field programmable gate arrays (FPGA), specialised processors that swiftly and accurately handle real-time data analysis.

“We chose EMD because it adapts seamlessly to the grinder’s changing acoustic environment. Stones produce transient, distinctive acoustic patterns that EMD easily recognises, even amidst background noise,” Dr Teo highlighted. “We specifically chose FPGA for its real-time processing capabilities and cost-effectiveness—crucial for adoption in small-scale commercial coffee settings.”

In extensive tests, the system reliably identified stones that closely resembled coffee beans with near-perfect accuracy, preventing damage to the burrs. However, Dr Teo acknowledged that there is room for improvement with respect to the detection of smaller, crushed stones, which are harder to distinguish acoustically.

“Detecting tiny fragments remains challenging, as their acoustic signatures can overlap and become masked by bean noise. We’re actively working to enhance our method by better utilising subtle acoustic cues embedded in the signal’s time-domain characteristics," said Dr Teo. “We already have a promising solution in the pipeline, and we hope to share it soon—so watch this space!”

Importantly, this innovative acoustic approach has significant potential for commercial translation. Easy to integrate without major modifications to existing machines, it offers cafés and smaller coffee businesses a practical, economical alternative to large-scale screening methods, which most lack the resources to afford.

“Ultimately, our goal is straightforward. We want to prevent stones from ever damaging a coffee grinder again,” Dr Teo said. “By developing a reliable detection method that enhances the efficiency and longevity of coffee grinders, we could benefit café operations and the coffee industry as a whole.”

Looking ahead, the team is focused on refining their algorithm’s sensitivity, aiming for widespread adoption across the diverse coffee-grinding scene.