First UK outing for Ilapak’s hygienic 6000 series

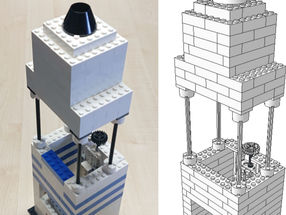

ILAPAK is using PPMA as the UK launch-pad for two new machines that respond to the increasingly exacting hygiene demands of the food industry. The Delta 6000 is the industry’s first full wash down horizontal form fill seal (HFFS) system, whilst the new Vegatronic 6000 vertical bagger offers the ultimate in bag style flexibility on an ultra-hygienic machine.

“The ethos behind the 6000 series is to be the most hygienic machine available. The range was designed with high care food environments in mind, but we are increasingly finding that demand for sanitary construction is spilling over into other industries,” says Tony McDonald, sales & marketing director at ILAPAK UK.

Delta 6000: hygienic MAP machine

The Delta 6000 is ideal for MAP applications where performance and sanitary design are top priorities, frommeat, fish, cheese and sandwich production towet-wipe, ready meal and bakery lines. At PPMA it will be shown running grab bags for sandwiches. Complete IP65 protection enables full wash down capability, even of the sealing elements. The machine’s ultra-hygienic design has been achieved through full stainless steel execution, isolating the electrical cabinet from the main machine frame, smooth, angled surfaces without recesses, tubular legs and an easy-clean infeed.

The versatile flowrapper can run the full gamut of complex films and laminates of up to 120 micron in thickness. Seal integrity is guaranteed through a revolutionary new sealing system with parallel opening feeding rollers. Operators can adjust the pressure on the fin seal, resulting in high integrity hermetic seals and enhanced film control. The new high speed, long dwell sealing system enables running speeds of up to 200 ppm - previously unheard in MAP applications.

Users of the Delta 6000 will also benefit from shorter lead times and lower cost of ownership (COO) as a result of the machine’s unique modular design. Customers can customise their machine by selecting only the modules they need, and can easily add modules such as film auto-splicing, gusseting, die-cutting and labelling for resealable packs, automatic in-feed and even a completely new jaw set up at a later date.

Smart: the savvy choice

The other horizontal machine under the spotlight at PPMA is theSmart, a cost-effective flowrapper that offers the same modular construction and hygienic design as ILAPAK’s higher-end models.

“With the Smart, users are getting design features that would usually only be found on a £60,000 flowrapper, on a machine that costs half that. Cantilevered hygienic design, ABB electronics, colour touchscreen, and no-product no-bag and misplaced product functions are all part of the deal,” says McDonald.

The Smartis capable of producing pillow packs and gusset packs from hot and cold seal films of up to 50 micron in thickness, making it an ideal choice for craft bakeries and fresh produce lines.

Vegatronic 6000: versatile vertical bagger

As an expert in both the vertical and horizontal packaging spaces, ILAPAK will also be showing its latest advancement in vertical bagging - theVegatronic 6000. Characterised by unrivalled versatility and access for cleaning, this game-changing piece of kit is already generating interest from confectionery, bakery, snacks, frozen food and salad producers looking for an easy-to-clean bagger to pack their product into a variety of vertical styles.

Operating at speeds of up to 200 cycles per minute thanks to digital servo drives, the continuous motion bagger can pack both dry and wet products intopillow, block bottom, Quattro, Easy Pack and Doy style formats with fast and tool-less changeover. The open frame design allows the operator to see right through the machine to view the film path and alignment. The film carriage design enables packs of up to 300 mm in width to be produced from virtually any film, including heavy laminates and thick polyethylene.

Complete IP65 protection has been achieved through full stainless steel execution, isolating the electrical cabinet from the main machine frame, the absence of any welds and smooth, angled surfaces without recesses. This ultra-hygienic construction enables full wash down capability, even of the sealing elements.

The machine’s modular design makes maintenance quicker and easier, as individual sections can be accessed really easily. Maintenance is further assisted by an innovative system for fast removal of the forming tube, and full access to all areas of the film reel path due to the machine’s open frame design.

Vegatronic 2300 OF: seal integrity for salads

In another development on the vertical side, ILAPAK, one of the pioneers of ultrasonic sealing, is previewing its new Vegatronic 2300 OF(open frame) bagger with ultrasonic sealing technology. This is the first time in the UK that ILAPAK has shown its ultrasonic technology on a narrower 320mm jaw width, which is particularly suited to bagged salad, grated cheese and liquid applications.

“More and more salad producers are asking us for ultrasonic sealing owing to its ability to improve seal integrity and drastically reduce waste, whilst reducing film costs and energy consumption,”says Chris Creasy, Divisional Manager at ILAPAK UK.

Because ultrasonic seals are 70% stronger than conventional heat seals,saladproducers who switch to ultrasonic can expect dramatic reductions in the number of leaking bags. Ultrasonic sealing can also seal through any leaves which may have accidentally been deposited in the seal area.

With its hygienic execution, the Vegatronic 2300 OF has been engineered to stand up to the challenging wash down requirements of the salad and produce industries. There are no cavities where dirt and debris can accumulate, there is minimal use of assembled parts, the electrical cabinet is isolated from the main frame and the machine is available rated to IP65 or IP66.

ILAPAK’s Vegatronic 2300 OF can run off the full range of bag styles that can be produced on a VFFS machine, including pillowpacks, block bottombags and Quattroand pouch packs.

Weightronic 14-25: multi-head weighing for multiple applications

ILAPAK can supply any of its VT series vertical baggers in tandem with a high speed multi-head combination weigher. At PPMA, it will be demonstrating the hygienic build quality and accuracy of its weighers via theWeightronic 14-25 model. This 14-head weigher is ideal for weighing IQF products, prepared vegetables, salad leaves and baked goods, to name but a few applications.