Lapp Group shows strong growth

Higher turnover, increased profit, more employees

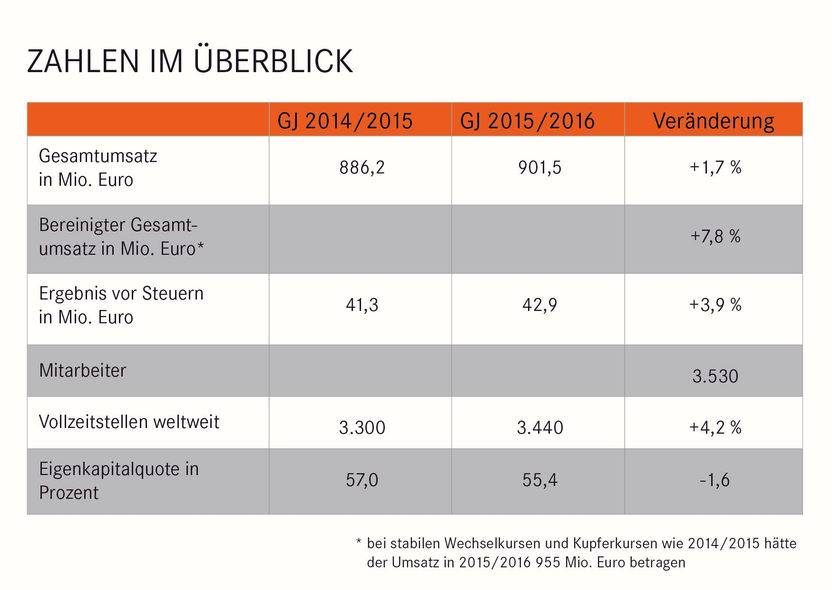

All signs point to continued growth for the Lapp Group. In the previous financial year 2015/2016 (1 October to 30 September), the global market leader for integrated solutions for cable and connection technology from Stuttgart was able to increase its performance considerably. The net sales increased to EUR 901.5 million. "We have increased our customer base worldwide. We are very proud of this, as it shows just how well-received our products and services are on the market," says Andreas Lapp, Chairman of the Board at Lapp Holding AG. Earnings before taxes increased by 3.9 percent to EUR 42.9 million. The number of full-time positions increased by 140 to 3,440, while a total of 3,530 employees work at Lapp.

Lapp Group

Andreas Lapp, Chairman of the Board at Lapp Holding AG.

Lapp Group

Andreas Hermann, Member of the Board for Finance at Lapp Holding AG.

Lapp Group

Healthy earnings and financial situation

The earnings and financial situation at the Lapp Group was also very healthy in the previous financial year. The equity capital ratio in percent is 55.4 and therefore remains at a high level. Member of the Board for Finance Andreas Hermann said: "The Lapp Group is in very good shape and continues to grow healthily. Thanks to our 2020 Strategy, the course is set for sustainable and stable growth in the coming years as well."

Business development

Despite the difficult situations in some sectors, the Lapp Group was able to hold its own. If the copper prices had not continued to sink considerably across the course of the year, and if the exchange rates had also remained stable, the company would have been able to record a turnover increase of almost eight percent. The negative influences are mainly a result of the lower copper price, which sank by an annual average of 17 percent from EUR 527/100 kg to EUR 438/100 kg. As the actual price of a cable is calculated daily based on the current price of copper, the turnover automatically decreases when the copper prices sink. Negative currency developments outside the Eurozone also played a role. These factors combined to lower the net turnover by approximately six percent. This does not accurately reflect the actual performance of the company, however.

The Lapp Group was able to extend their business, for example, with the ready-to-connect system solutions under the ÖLFLEX® CONNECT name. The organisational requirements for marketing were optimised for the food industry and renewable energy target markets. Lapp is entering another new sector: the cabling of rail vehicles. The Lapp Group has created a complete product portfolio with ÖLFLEX® TRAIN and other brand products for this sector.

Varying development in the regions

Europe is the most important market for the Lapp Group with a 69 percent share in the total turnover. The turnover here grew by five percent to EUR 620.6 million. The most important single market is Germany, with a turnover share of almost 30 percent and an almost unchanged revenue of EUR 268.2 million. In Europe, the turnovers in Benelux, Spain, Poland and Italy have developed particularly positively. The region of America (USA, Canada, Central and South America) managed to increase its turnover slightly by 1 percent to EUR 109.0 million. In Asia (with Africa, Australia and New Zealand), however, the turnover sank by nine percent to EUR 171.9 million for project-related reasons.

Investments to secure the future

The largest construction project was the new Lapp European headquarters at the company's home in Stuttgart-Vaihingen. Around 400 employees moved in there at the end of the year. The new building provides new opportunities to combine Lapp's strengths even more effectively and to provide even better support for customers throughout Europe, Africa, the Middle East and South America. The investment sum borne by Lapp Immobilien GmbH & Co. is approximately EUR 28 million. At EUR 20.3 million, the investment volume of the Lapp Group is on par with the previous financial year 2015/2016. Investments were also made in Lapp Russia, where a new management and logistics centre was opened. Other important projects were investments in the equipment at the production plants and the continued roll-out of the new SAP software ECC 6.0.

Innovations and examples of application

The Lapp Group was awarded the TOP 100 seal in 2016 for its innovation. This seal is awarded by a committee under the scientific direction of innovation researcher Nicolaus Franke, from the University of Vienna. Processes which aid companies in being innovative are honoured in particular. Georg Stawowy, Member of the Board for Technology & Innovation: "We want to tap into new markets with our innovations, but we also always want to offer the newest and best products." A strategic partnership with OPVIUS (formerly Belectric OPV), market leader in organic photovoltaic systems, will aid in the development of new connector technology for the future-oriented technology of organic photovoltaics. Some current examples of innovation and projects at the Lapp Group:

- ÖLFLEX® CONNECT SERVO: The new generation of servo assemblies[1]: Lapp has collected and standardised all the assembly activities globally under the new name ÖLFLEX® CONNECT. To this end, Lapp built up corresponding engineering, production and assembly capacities in America, Europe and Asia. The number of sites thus increased from 5 in 2015 to 12 in 2016. The new ÖLFLEX® CONNECT SERVO is a particularly successful product. This is a new generation of servo products with which the connection solutions for electrical drives are improved, made more efficient and are available worldwide in the same high quality. One of the most important customers of ÖLFLEX® CONNECT SERVO is the EMAG Group, a leading manufacturer of production systems for precise metal parts based in Salach near Stuttgart.

- Antistatic cables: The Lapp Group was the first manufacturer in the world to develop cables to help prevent catastrophic events. These antistatic cables immediately discharge static charges and provide greater safety in locations where sparks caused by static charges can lead to disasters, for example on oil drilling platforms, in refineries or when processing wood or flour. They are already used by the Norwegian company Aker Solutions on oil drilling platforms.

Successful human resources policy

U.I. Lapp GmbH won first place in the corporate competition "Family as a success factor" in the category "Medium-sized enterprises" in June 2016. The prize is awarded by the German Federal Ministry for Family Affairs, Senior Citizens, Women and Youth. More than 400 companies throughout Germany had applied for the award by providing information on their measures and concepts for balancing work and family life. Alongside the numerous flexible working time models, decisive points for the victory were mainly measures such as family-friendly shift schedules with a shift exchange platform in the logistics departments, programmes to stay in contact and re-entry programmes for parents on parenting leave, a consultation workshop on care topics, training employees to be care guides, as well as the numerous healthcare offers. Another key factor is the permanent awareness of the managers to run the company in a "family-friendly and health-oriented" manner.

A further guarantee of the future-oriented human resources policy at Lapp is the apprenticeships. Lapp is currently training 61 young people in Germany in eleven professions and courses of study at the Cooperative State University. In addition, the Lapp Group also offers entry qualifications in cooperation with the Chamber of Industry and Commerce as preparation to becoming a machine and equipment operator, or to become a warehouse specialist or IT specialist. Among others, 12 refugees from Eritrea, Cameroon, Syria, Afghanistan, Kosovo, Somalia and Iran are using this opportunity.

"The success story of the Lapp Group can only continue when the focus is on the people," says Member of the Board for Human Resources Dr Hilmar Döring. A group-wide personnel development concept was conceived to provide the right programme for further development for different target groups. The aim is to further increase the number of managers from within the company.

Positive outlook for the current financial year

The Lapp Group is expecting a slight turnover growth for the current financial year 2016/2017, too. Turnover increases are expected above all in Europe. The company believes the purchase in October last year of the Italian company CEAM Cavi Speciali, one of the leading manufacturers of data cables for special industrial applications, will provide important impetus. With this purchase, Lapp is looking to strengthen its position as market leader in industrial data transfer systems. Andreas Lapp: "We have put everything on the right track to secure sustainable growth for our company and customers over the next few years, despite the increased social and political tension."

[1] Assembly means the further processing of cables, connectors and other system products to create ready-to-use systems. Servo assemblies are multi-core cables together with connectors to connect control and drive in industrial machines.